This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Team develops microelectrodes with soft, stretchable and permeable properties for implantable bioelectronic devices

Electronic devices that can be attached to the skin or even implanted in the body will become more and more prevalent in near-future technology. Such "implantable bioelectronics" are envisaged as having a wide range of uses from medical technology to the emerging field of augmented reality, and a research team led by The Hong Kong Polytechnic University (PolyU) has developed a type of microelectrode that is uniquely suited to devices of this kind.

Their pioneering study entitled "Wafer-patterned, permeable, and stretchable liquid metal microelectrodes for implantable bioelectronics with chronic biocompatibility" was recently published in Science Advances.

Compared with conventional electronics, materials used for wearable or implantable bio-electronic technology require specific properties that are difficult to bring together. They must be stretchable, soft and permeable enough to survive in the human body without causing discomfort or harm to the user. Meanwhile, like everyday household devices, bioelectronics still depend on electrodes that are highly electrically conductive and can be patterned into microscale circuitry.

Led by Prof. Zijian Zheng, chair professor of soft materials and devices and professor of the Department of Applied Biology and Chemical Technology, the interdisciplinary research team comprises members from PolyU's School of Fashion and Textiles, Department of Biomedical Engineering, Department of Applied Biology and Chemical Technology, Research Institute for Intelligent Wearable Systems (RI-IWEAR) and Research Institute for Smart Energy (RISE), as well as from City University of Hong Kong and the Hong Kong Center for Cerebro-Cardiovascular Health Engineering.

The team has overcome several technical limitations to advance the field of wearable technology and invented a method of producing unprecedentedly soft, stretchable and permeable electrodes for implantable bioelectronics.

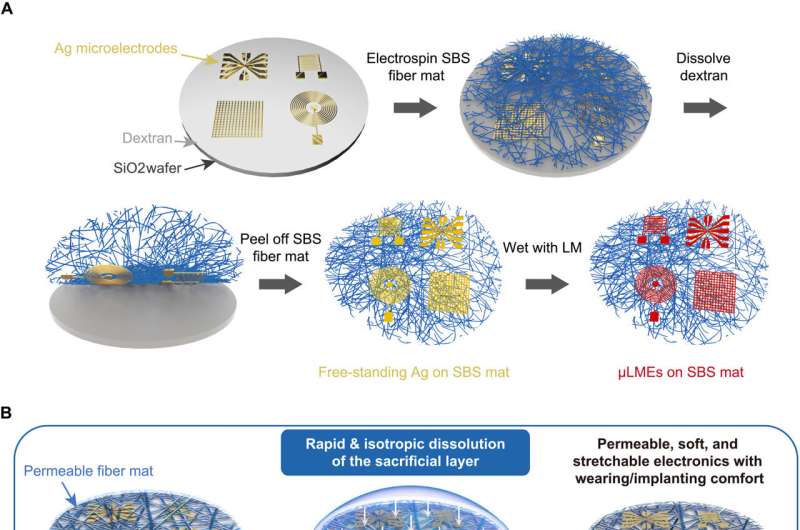

The key step in the fabrication process is the electrospinning of a fibrous polymer onto silver (Ag) micropatterns, resulting in an array of liquid metal microelectrodes (μLMEs) that can be patterned at ultrahigh density—up to 75,500 electrodes per square centimeter, thousands of times higher than previously achieved—and that have long-term biocompatibility. The μLMEs can be comfortably worn on human skin, while a specific application in animal brain monitoring has also been demonstrated.

Previously, biocompatible electronics were fabricated on porous elastomers, but the porosity and roughness of these substrates limit the patterning resolution and hence the electrode density. By depositing electronic circuitry onto fibrous polymer substrates through the technique of photolithography, the team successfully overcame this obstacle, achieving μLMEs with tissue-like softness, high conductance under severe strain and long-term biocompatibility.

A liquid metal alloy known as eutectic gallium indium (EGaIn) was used as the conductive component of the μLMEs, as it has a low melting temperature and retains its conductivity under extreme strain, while being soft and highly biocompatible. The fabrication process involves depositing circuitry patterns comprising EGaIn onto an electrospun, a permeable "fiber mat" of the polymer poly (styrene-block-butadiene-block-styrene). This created soft, stretchable electronics that can be comfortably worn and implanted.

The concept of a super-elastic fiber mat was first developed by Prof. Zheng's team in 2021, and is now adopted in the newly developed μLMEs to guarantee a complete photolithographic transfer of the electrode micropatterns from the Ag template, in contrast to the partial transfer achieved when using impermeable substrates.

Apart from being soft, liquid-permeable and air-permeable, μLMEs are also highly stretchable, and their electrical resistance increases only slightly after repeated cycles of stretching and release under high strain. When attached to human skin, an electronic patch fabricated from μLMEs leaves only trace or even no residues after being subjected to pressure. This is a promising property for wearable electronics, for which there is expected to be a huge market with applications in physiological monitoring, medical diagnosis and interactive technology.

Most notably, the softness and stretchability of the μLMEs also make them ideal for implantation at the neural interface for brain monitoring. The team synthesized an array of μLMEs with a small electrode diameter and high channel density to serve as an electrocorticography signal receiver in a rat brain. With similar mechanical properties to brain tissue, the μLMEs attached closely to the cortical surface and accurately recorded neural signals in vivo. When the sleeping rat sent out discernible brain waves typical of non-REM sleep, the μLME array reliably detected somatosensory evoked potentials in response to electrical stimuli applied to different parts of its body.

As associate director of RI-IWEAR and Lead Investigator at RISE, Prof. Zheng stated, "Thanks to the combination of photolithography and soft, permeable SBS fiber mats, microelectrodes with unprecedented resolution and biocompatibility are realized. The technological advancement in medical and augmented reality fields can be pushed forward by these μLMEs, which overcome previous technical limitations to the fabrication of bioelectronics."

More information: Qiuna Zhuang et al, Wafer-patterned, permeable, and stretchable liquid metal microelectrodes for implantable bioelectronics with chronic biocompatibility, Science Advances (2023). DOI: 10.1126/sciadv.adg8602

Journal information: Science Advances

Provided by Hong Kong Polytechnic University