This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Scientists develop an electrically driven organic semiconductor laser

Scientists at St Andrews are leading a significant breakthrough in a decades-long challenge to develop compact laser technology.

Lasers are used across the world for a huge range of applications in communications, medicine, surveying, manufacturing and measurement. They are used to transmit information across the internet, for medical treatments, and even in the face scanner on phones. Most of these lasers are made from rigid, brittle, semiconductor crystals such as gallium arsenide.

Organic semiconductors are a newer class of electronic material. Flexible, based on carbon and emitting visible light, they enable the simple fabrication of electronic devices. They are now widely used for the OLED (organic light-emitting diode) screens found in most mobile phones.

A limitation of organic semiconductor lasers is that they typically need another laser to power them. Researchers have been working to overcome this limitation for 30 years, so it is particularly significant that scientists at the University of St Andrews have recently developed an electrically driven organic semiconductor laser.

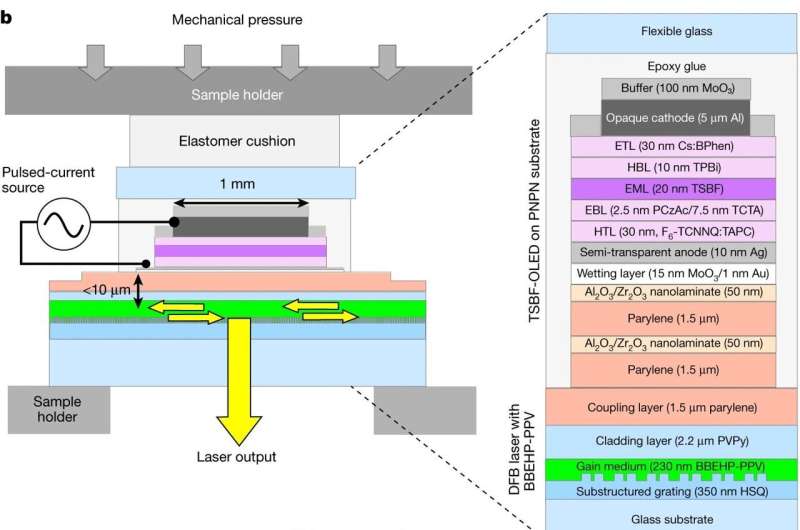

The team made this breakthrough, reported in the journal Nature, by first making an OLED with world-record light output and then carefully combining it with a polymer laser structure. This new type of laser emits a green laser beam consisting of short light pulses.

For now, this is mainly a scientific breakthrough, but with future development the laser could potentially be integrated with OLED displays and allow communication between them, or be used for spectroscopy for the detection of disease and environmental pollutants.

Prof Ifor Samuel commented, "Making an electrically driven laser from organic materials has been a huge challenge for researchers across the world. Now, after many years of hard work, we are delighted to have made this new type of laser."

Prof Graham Turnbull added, "We expect this new laser to use less energy in its manufacture, and in the future will generate laser light across the visible spectrum."

More information: Ifor Samuel, Electrically driven organic laser using integrated OLED pumping, Nature (2023). DOI: 10.1038/s41586-023-06488-5. www.nature.com/articles/s41586-023-06488-5

Journal information: Nature

Provided by University of St Andrews