This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Monolithically integrated semiconductor lasers with silicon photonic circuits

Silicon (Si) photonics has recently emerged as a key enabling technology in many application fields thanks to the mature Si process technology, the large silicon wafer size, and Si optical properties. However, the inability of Si-based materials to efficiently emit light requires the use of other semiconductors for light sources.

III‑V semiconductors, i.e., materials made with elements of the III- and V- columns from the periodic table of elements, are the most efficient semiconductor laser sources. Their monolithic integration on Si photonic integrated circuits (PICs) has been considered for decades as the main challenge for the realization of fully integrated, dense, Si photonics chips. Despite recent progress, only discrete III-V lasers grown on bare Si wafers have been reported so far.

In a new paper published in Light Science & Application, a team of European scientists from France, Italy and Ireland, led by Professor Eric Tournié from the University of Montpellier (France), has now unlocked the efficient integration of semiconductor lasers onto Si-photonics chips and light coupling into passive photonic devices.

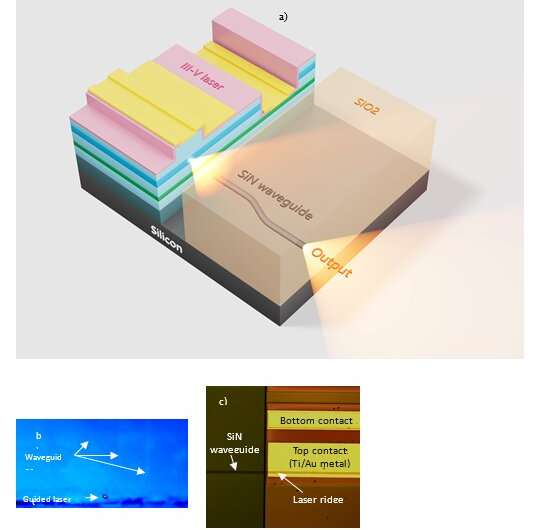

Their approach relied on three pillars: the Si-PIC design and fabrication, the III-V material deposition, and the laser fabrication. For this proof-of-concept, the PIC was made of transparent, S-shaped, SiN waveguides embedded in a SiO2 matrix. The SiO2/SiN/SiO2 stack was etched away in recessed areas to open Si windows for the deposition of the III-V material. It was crucial to preserve a high crystal quality of the Si surface after etching. GaSb technology was selected as the III-V material, as it can emit by design throughout the entire mid-infrared wavelength range, where many gases have their fingerprint absorption lines.

Molecular-beam epitaxy (MBE), a technique operating under ultra-high vacuum, was used to grow the semiconductor layer stack. The scientists had previously shown that this technique allows removal of a specific defect that usually occurs at the Si/III-V interface and kills the devices. Further, MBE allows to precisely align the laser part that emit light with the SiN waveguides.

Finally, a microelectronics process was used to create diode lasers from the epitaxial layer stack. At this stage, high-quality mirrors must be created through plasma etching in order to achieve laser emission. In spite of the process complexity, the performance of these integrated diode lasers were similar to those of diode lasers grown on their native GaSb substrate. Further, the laser light was coupled into the waveguides, with a coupling efficiency in line with theoretical calculations.

The scientists summarize the work: "The different challenges (PIC fabrication and patterning, regrowth on a pattern PIC, etched-facet laser processing in recessed areas, etc.) due to the particular architecture of the final devices were all overcome to demonstrate laser emission and light coupling into passive waveguides, with a coupling efficiency in line with theoretical calculations.

"Although demonstrated with mid-infrared diode lasers targeting gas sensing applications, this approach can be applied to any semiconductor materials system. In addition, it can be scaled up to any Si-wafer size up to at least 300 mm diameter, epitaxial reactors being available.

"The reported method and technique will open new avenues for future Si-photonics integrated circuits. They solve a longstanding problem, and lay the foundation for future low-cost, large-scale, fully-integrated photonic chips."

More information: Andres Remis et al, Unlocking the monolithic integration scenario: optical coupling between GaSb diode lasers epitaxially grown on patterned Si substrates and passive SiN waveguides, Light: Science & Applications (2023). DOI: 10.1038/s41377-023-01185-4

Journal information: Light: Science & Applications

Provided by Chinese Academy of Sciences