This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Femtosecond laser technique births 'dancing microrobots': A breakthrough in multi-material microfabrication

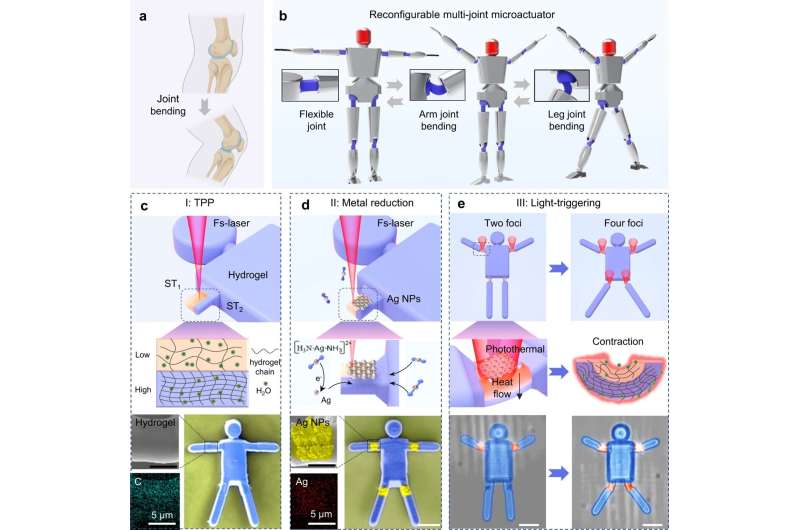

A research team led by Prof. Wu Dong from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) proposed a femtosecond laser 2-in-1 writing multi-material processing strategy to fabricate micromachined joints composed of temperature-sensitive hydrogels and metal nanoparticles, and developed multi-jointed humanoid micromachines with multiple deformation modes (>10). The results were published in Nature Communications.

In recent years, femtosecond laser two-photon polymerization, as a true three-dimensional fabrication technique with nanoscale precision, has been widely employed to produce various functional microstructures. These microstructures have shown great potential in areas such as micro-nano optics, microsensors, and microelectromechanical systems. However, the challenge remains in leveraging femtosecond lasers for multi-material processing and further constructing micro-nano mechanics with multi-modalities.

In this study, the femtosecond laser dual-function fabrication strategy involves using asymmetric two-photon polymerization to create hydrogel joints and locally depositing silver nanoparticles (Ag NPs) via laser reduction within the joints. This asymmetric light-polymerization technique induces anisotropy in cross-linking density within specific areas of the hydrogel micro-joints, ultimately enabling directional and angular-controllable bending deformations.

The in-situ laser reduction deposition allows for precise fabrication of silver nanoparticles on the hydrogel joints. These nanoparticles exhibit strong photothermal conversion effects, enabling the multi-joint micromachinery to showcase ultra-fast response times (30 ms) and extremely low driving power (<10 mW) characteristics.

In particular, eight micro-joints were integrated into a humanoid micro-mechanism. Subsequently, utilizing spatial light modulation technology, multi-focal beams were achieved in 3D space to precisely stimulate each micro-joint.

The collaborative deformation between multiple joints enables the humanoid micromachine to achieve various reconfigurable deformation modes, ultimately leading to a "dancing microrobots" at the micrometer scale. Lastly, as a proof of concept, by designing the distribution and deformation direction of the micro-joints, a dual-joint miniature mechanical arm can collect several micro-particles in both parallel and divergent directions.

The femtosecond laser dual-function fabrication strategy can construct deformable micro-joints in various 3D micro-structured areas, realizing multiple reconfigurable deformation modes. In the future, micromachinery with various deformation modes will open broad prospects in applications such as micro-goods collection, microfluidic manipulation, and cellular operations.

More information: Chen Xin et al, Light-triggered multi-joint microactuator fabricated by two-in-one femtosecond laser writing, Nature Communications (2023). DOI: 10.1038/s41467-023-40038-x

Journal information: Nature Communications

Provided by University of Science and Technology of China