This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

The perfect pour: Model predicts beer head features

From creating drinks with distinctive looks to providing aromas for connoisseurs, beer foam is big business. The complex interplay between the components of a beer, the vessel from which it's poured, and the glass it's poured into has garnered plenty of attention from researchers, brewers, and drinkers. A new study looks to provide the most accurate predictions for how a beer will foam.

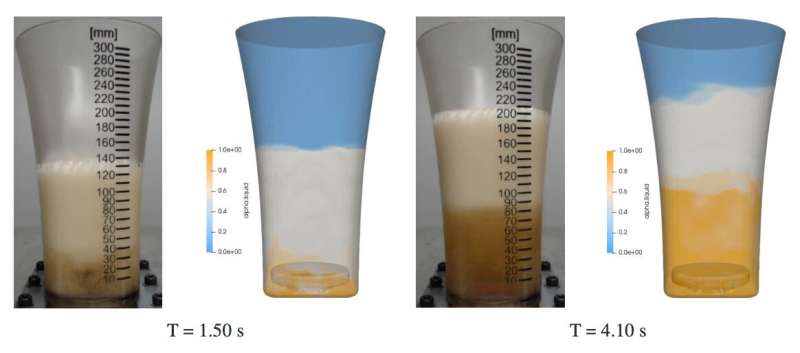

Researchers have analyzed brewing with numerical simulations to predict an array of beer foam features. Publishing their work in Physics of Fluids, Lyu et al. demonstrate that their model can determine foam patterns, heights, stability, beer/foam ratio, and foam volume fractions.

The study presents the first use of a computational approach called a multiphase solver to tackle beer heads.

"Simulation of a bottom-up pouring process using a multiphase solver is a complex task that involves modeling the physical and chemical interactions that occur during the process, such as fluid dynamics, heat and mass transfer, and chemical reactions," said author Wenjing Lyu.

"By using a multiphase solver, it is possible to accurately predict the behavior of the system and optimize the design of the nozzle outlets and the cup geometry to ensure the fastest possible bottom-up pouring under various conditions such as pressure, temperature, and carbonation."

To tackle this task, the group partnered with Einstein 1, a startup developing a new bottom-up tapping system in which the nozzle pushes up a movable magnet on the bottom of a glass to create a temporary inlet. As the glass fills, the magnet moves back into place and the beverage is ready to drink. After repeatability studies to establish stable pouring conditions, they assembled a model that was then validated with experiments.

The group found that foam from Einstein 1's tapping system is generated only in the first moments of pouring. Higher temperatures and pressures yielded more foam.

After that, beer's liquid phase kicked in. Determined in large part by bubble size, the beer's foam phase slowly decayed, taking approximately 25 times longer to fully fizzle out than it took the foam to form.

Alongside further optimizing their computational approaches, the group next looks to study the effects of nozzle shapes.

"This will help in controlling foam formation, reducing consumption and pouring time, and improving the overall efficiency of the pouring process," Lyu said. "By accurately simulating the foaming process, our model can help to improve the quality of the final product, reduce costs, and increase productivity in industries such as food and beverage, chemical, and others."

More information: Wenjing Lyu et al, Experimental and Numerical Investigation of Beer Foam, Physics of Fluids (2022). DOI: 10.1063/5.0132657

Journal information: Physics of Fluids

Provided by American Institute of Physics