3D nanocomposites boost heat dissipation in electronics

Scientists from Skoltech developed a self-assembled 3D nanocomposite with outstanding in-plane and out-of-plane heat conductivity, high electrical resistivity, and good hydrophobicity, which have a wide range of potential uses in packaging and electronics for thermal management applications. The study, describing scalable fabrication and composite properties, was published in Polymers.

The last few decades have witnessed an advance in electronics technology, with the development of devices that are highly integrated, lightweight, and portable. However, as the devices get smaller, so does the space for accommodating the internal working components. This has created an issue of improper heat dissipation in devices, since conventional heat sink materials are bulky and cannot be integrated into them. Currently, several substrate materials can act as heat diffusers as thin films, but most diffuse heat in the in-plane direction isotropically. This could create thermal interference with neighboring components of a device.

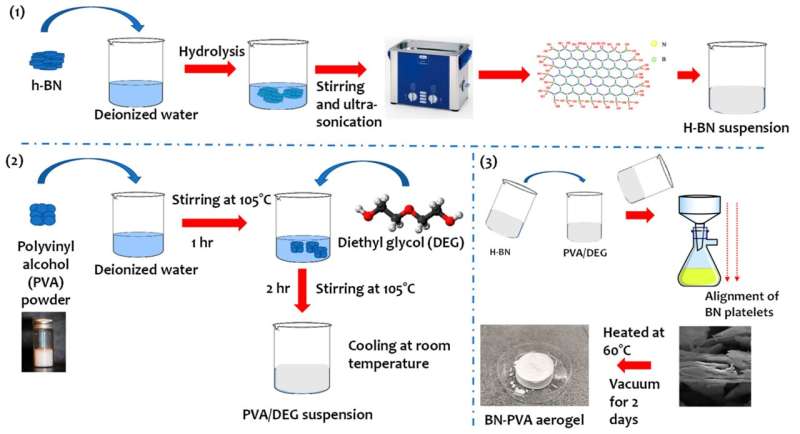

Researchers from Skoltech found a solution to this problem through the development of 3D polyvinyl alcohol (PVA) aligned boron nitride (BN) aerogel framework nanocomposites. The composite showed excellent thermal conductivity, stability and wettability behavior, which is extremely pertinent to thermal management in electronics.

"It is necessary to align the filler materials inside the polymer matrix for the rapid dissipation of heat in electronic devices for the efficient transfer of phonons in a segregated BN filler-based PVA thermal channel. The orientation entails the bridging and structuring effect of a polymer with highly oriented BN at the nano-level," says Mohammad Owais, Skoltech Ph.D. student.

"We know that the 3D structure is excellent for boosting heat management capability, and that pushed us towards using aerogel—a 3D network material that has low density, high thermal conductivity, is lightweight, and has a changeable surface chemistry, meaning it is ideal to form the 3D skeleton as a framework for our composite system."

Apart from the optimized thermal properties, other major advantages of the nanocomposite are high electrical resistivity and good hydrophobicity, explains Owais. "Good wettability and electrical insulation are significant parameters of the composite when the electronic motherboard with integrated circuits is vulnerable to short-circuiting and malfunctioning. We need thermal interface materials with good hydrophobicity when the ICs are subjected to water, making them water resilient."

Overall, the researchers believe these findings can act as a framework for designing 3D and 2D composites with novel heat dissipating patterns. "We may go for patenting soon as our already fabricated prototype films—aerogels after compressions—exhibit great flexibility with a robust structure," says Owais.

More information: Mohammad Owais et al, Scalable Fabrication of Thermally Conductive Layered Nacre-like Self-Assembled 3D BN-Based PVA Aerogel Framework Nanocomposites, Polymers (2022). DOI: 10.3390/polym14163316

Provided by Skolkovo Institute of Science and Technology