Discovery of new nanowire assembly process could enable more powerful computer chips

Researchers from Oxford University's Department of Materials have developed a technique to precisely manipulate and place nanowires with sub-micron accuracy. This discovery could accelerate the development of even smaller and more powerful computer chips.

In a newly published study, a team of researchers in Oxford University's Department of Materials led by Harish Bhaskaran, Professor of Applied Nanomaterials, describe a breakthrough approach to pick up single nanowires from the growth substrate and place them on virtually any platform with sub-micron accuracy.

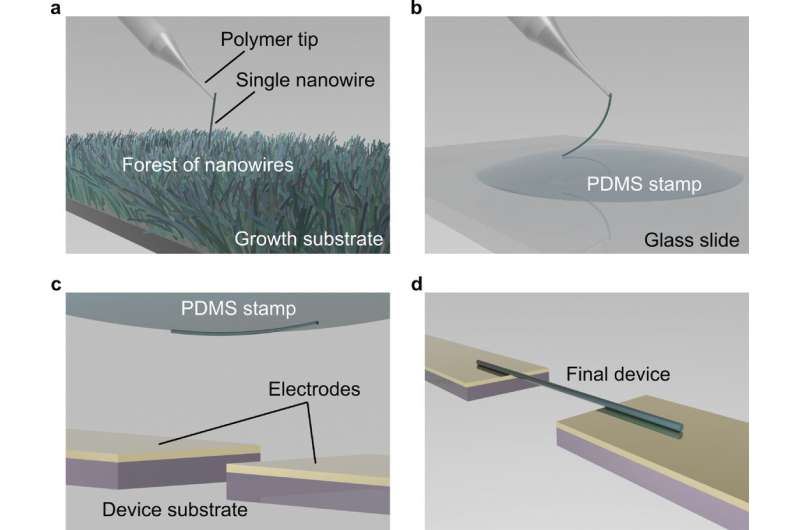

The innovative method uses novel tools, including ultra-thin filaments of polyethylene terephthalate (PET) with tapered nanoscale tips that are used to pick up individual nanowires. At this fine scale, adhesive van der Walls forces (tiny forces of attraction that occur between atoms and molecules) cause the nanowires to "jump" into contact with the tips. The nanowires are then transferred to a transparent dome-shaped elastic stamp mounted on a glass slide. This stamp is then turned upside down and aligned with the device chip, with the nanowire then printed gently onto the surface.

Deposited nanowires showed strong adhesive qualities, remaining in place even when the device was immersed in liquid. The research team were also able to place nanowires on fragile substrates, such as ultra-thin 50 nanometer membranes, demonstrating the delicacy and versatility of the stamping technique.

In addition, the researchers used the method to build an optomechanical sensor (an instrument that uses laser light to measure vibrations) that was 20 times more sensitive than existing nanowire-based devices.

Nanowires, materials with diameters 1,000 times smaller than a human hair and fascinating physical properties, could enable major advancements in many different fields, from energy harvesters and sensors, to information and quantum technologies. In particular, their minuscule size could allow the development of smaller transistors and miniaturized computer chips. A major obstacle, however, to realizing the full potential of nanowires has been the inability to precisely position them within devices.

Most electronic device manufacturing techniques cannot tolerate the conditions needed to produce nanowires. Consequently, nanowires are usually grown on a separate substrate and then mechanically or chemically transferred to the device. In all existing nanowire transfer techniques, however, the nanowires are placed randomly onto the chip surface, which limits their application in commercial devices.

DPhil student Utku Emre Ali (Department of Materials), who developed the technique, said, "This new pick-and-place assembly process has enabled us to create first-of-its-kind devices in the nanowire realm. We believe that it will inexpensively advance nanowire research by allowing users to incorporate nanowires with existing on-chip platforms, be it electronic or photonic, unlocking physical properties that have not been attainable so far. Furthermore, this technique could be fully automated, making full-scale fabrication of high quality nanowire-integrated chips a real possibility."

"A Universal Pick-and-Place Assembly for Nanowires" is published in the journal Small.

More information: Utku Emre Ali et al, A Universal Pick‐and‐Place Assembly for Nanowires, Small (2022). DOI: 10.1002/smll.202201968

Journal information: Small

Provided by University of Oxford