Using melt polymerization to fabricate robust covalent organic framework foams

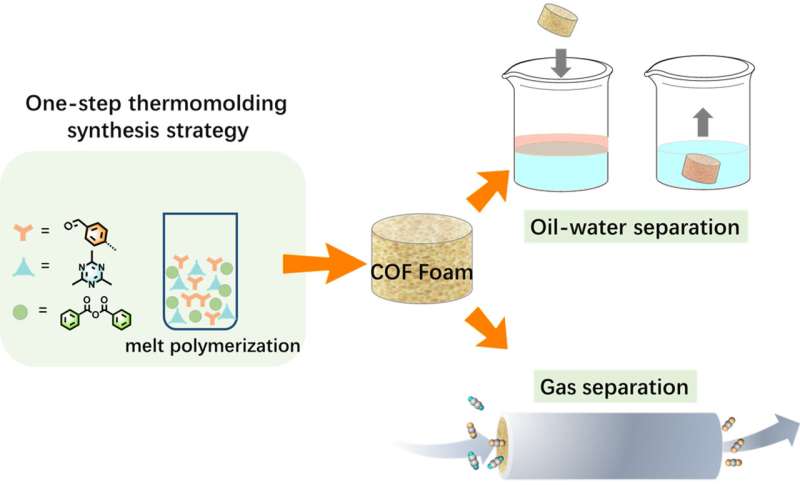

Adsorption-based (e.g., gas or liquid molecules) separation technologies have shown unique economic and environmental advantages in specific applications. In industrial applications, ideal high-efficiency adsorbents require not only high adsorption capacity/selectivity, but also good machinability, cycling, and mechanical stability. Thus, it is necessary to assemble the adsorbents into high-stability monoliths (e.g., spheres, membranes, aerogels, etc.). Recently, COFs, as an emerging class of advanced adsorbents, have demonstrated many heartening performances in numerous separation fields. However, most of the state-of-the-art COF adsorbents still suffer from issues such as low processability (mostly existing as microcrystalline powders), lack of stability (mostly built by the reversible bond linkages), and difficulty for scalable synthesis. Therefore, it is of great significance to create new strategies to produce highly robust COF monoliths (e.g., porous foams) for practical applications.

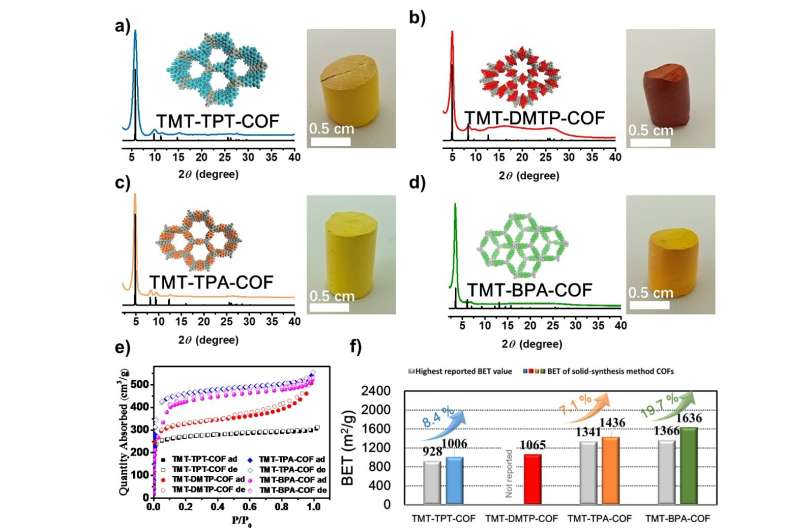

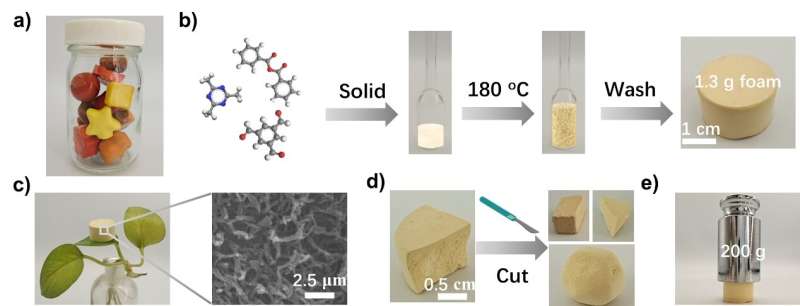

Melt polymerization methods are often used to prepare linear polymers. Since both monomers and polymers are in a molten state, it is easy to directly process and shape. Inspired by this, Zhang's group from Nankai University first introduced the "melt polymerization" strategy into COFs synthesis. By adding benzoic anhydride as a flux, a "one-step thermoforming" method was developed to prepare a series of olefin-linked COF foams. This is because the flux promoted the monomers to form a eutectic, which slowly crystallized upon heating, and finally solidified to form highly crystalline COF foams (density as low as 0.23 g/cm3).

This method not only can enhance crystallinity and porosity of the reported COFs, but also can produce new COFs that cannot be obtained by the traditional solvothermal methods. For example, a novel olefin-linked COF (NKCOF-12) with ultra-micropores (0.58 nm) was synthesized for the first time by this method. These obtained foams demonstrate excellent processability and mechanical properties which are suitable for adsorption and separation.

The oil-water selective adsorption experiments showed that these foams achieved highly efficient oil-water separation (up to 99% removal efficiency) with facile recycling and ultrahigh reusability (more than 100 cycles). Moreover, NKCOF-12 with the smallest pore size among all reported eclipsed stacking 2-D COFs was constructed. Attributed to its regular ultramicroporous channel (0.58 nm) and enriched binding sites, NKCOF-12 possesses excellent C2H2/CO2 separation performance with higher C2H2 purity (99.3%) than the benchmark materials. This work not only provides an opportunity for the construction of COF foams via melt polymerization but also significantly advances the development of COFs for practical applications. The results are published in Science China Chemistry.

More information: Penghui Zhang et al, Melt polymerization synthesis of a class of robust self-shaped olefin-linked COF foams as high-efficiency separators, Science China Chemistry (2022). DOI: 10.1007/s11426-022-1224-3

Provided by Science China Press