New metabolic engineering strategy improves bioproduction of polymer raw materials

A research group, consisting of doctoral student Fujiwara Ryosuke, Associate Professor Tanaka Tsutomu (both of Kobe University's Graduate School of Engineering) and Research Scientist Noda Shuhei (RIKEN Center for Sustainable Resource Science), has succeeded in improving the yield of target chemical production from biomass. They achieved this through metabolically engineering the bacteria used in bioproduction, so that it would use different kinds of sugar absorbed from the biomass for separate aims.

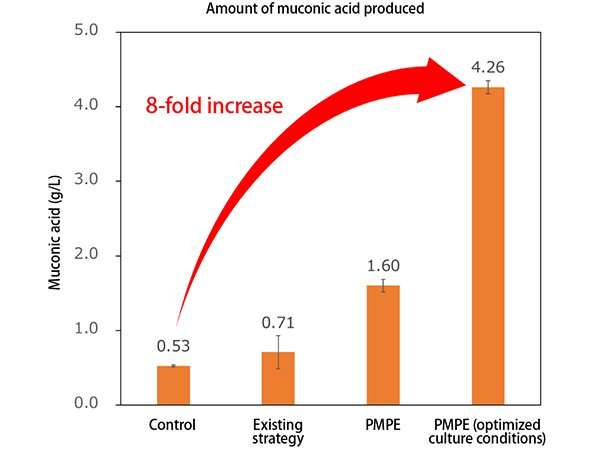

There are problems involved with using microbes to produce target chemicals. If the microbes use the carbon sources (sugars) for their own propagation, target chemical production decreases. On the other hand, suppressing this propagation causes the microbes to weaken, resulting in an overall decline in production. To resolve this issue, the research team developed a new strategy called parallel metabolic pathway engineering (PMPE), allowing them to control both target chemical production and microbe propagation. They used this approach to alter E. coli bacteria in order to successfully boost the production of the nylon precursor muconic acid.

Using the selected carbon source solely for target chemical production and deploying the remaining sources for microbe propagation will bring about great advances in the production of aromatic compounds and raw materials for medical and chemical products. The results of this research were first published in Nature Communications on January 14.

Industry relies on fossil fuels as raw materials for producing various products. However, producing petroleum-derived compounds increases the amount of atmospheric CO2, causing a multitude of environmental problems.

Consequently, there is a need to develop biorefinery technologies that involve using microbes to produce chemical compounds from naturally abundant renewable resources such as tree and plant matter. Biomass-derived products have the advantage of being carbon neutral; they do not increase the amount of CO2 in the atmosphere. It is hoped that using biomass to produce various useful compounds can form a basis for a low-carbon society, reducing the amount of atmospheric CO2.

Muconic acid is a useful chemical that can be easily converted into adipic acid, an ingredient in nylon production. It is also used as a raw material in the production of medical and chemical products. However, it is currently chemically synthesized from petroleum resources. It is hoped that a fermentation method could be developed using microbes and renewable plant-based resources with milder reaction conditions and fewer by-products.

However, there are problems with using microbes to produce target chemicals from biomass. There are many cases in which microbes using biomass propagate themselves instead of producing the target chemical. However, altering the metabolism to prevent the microbes from increasing causes them to weaken, meaning that the target chemicals cannot be synthesized. The balance between microbe self-propagation and target chemical production is big issue.

To solve this dilemma, the research team developed PMPE in which they separated sugar utilization between microbe propagation and target chemical production, allowing them to control each process independently.

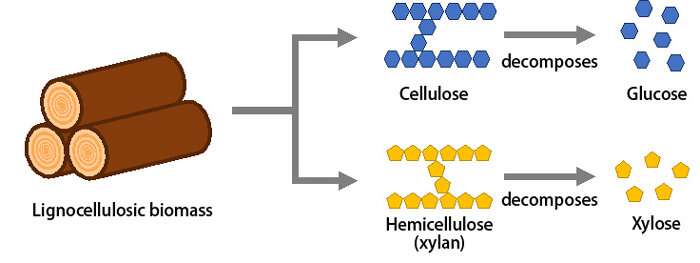

Lignocellulosic biomass, which does not compete with global food supplies, is made up of glucose and xylose sugars (Figure 1). The research team developed a metabolic strategy which involved modifying the E. coli bacteria so that it would utilize glucose for target chemical production and xylose for microbe propagation.

In regular microbes, glucose and xylose use the same metabolic pathway and are both utilized for microbe growth and target chemical production (as shown in Figure 2). This reduces the amount of target chemical synthesized because the microbes absorb the sugars to produce and maintain the elements and energy that they require to live.

As shown in Figure 2, dividing the microbes' metabolic pathway allows each sugar to be used independently with all the glucose being used for target chemical production and all the xylose being used for microbe propagation and maintenance. This allowed a greater yield of the target chemical to be produced because none of the glucose was being used for microbe growth.

This research group introduced a metabolic pathway to the modified E. coli for synthesizing muconic acid. The modified E. coli used the glucose and xylose, leading to the production of the target chemical. The researchers succeeded in producing 4.26 g/L of muconic acid with a yield of 0.31g/g-glucose (Figure 3). This is considered the highest yield in the world, proving the effectiveness of the PMPE strategy.

Subsequently, the researchers investigated whether the PMPE strategy could be applied to the production of target chemicals other than muconic acid. As a result, they successfully increased yields of the essential amino acid and aromatic compound phenylalanine, and 1,2- propanediol, which is used as an additive in medicines and food products. These results have shown that PMPE is a versatile technique that can be used to efficiently produce a variety of compounds.

More information: Ryosuke Fujiwara et al. Metabolic engineering of Escherichia coli for shikimate pathway derivative production from glucose–xylose co-substrate, Nature Communications (2020). DOI: 10.1038/s41467-019-14024-1

Journal information: Nature Communications

Provided by Kobe University