Ice lithography: Opportunities and challenges in 3-D nanofabrication

Nanotechnology and nanoscience are enabled by nanofabrication. Electron-beam lithography (EBL), which makes patterns down to a few nanometers, is one of the fundamental pillars of nanofabrication. In the past decade, significant progress has been made in electron-beam-based nanofabrication, such as the emerging ice lithography (IL) technology, in which ice thin-films are used as resists and patterned by a focused electron-beam. The entire process of IL nanofabrication is sustainable and streamlined because spin coating and chemical developing steps commonly required for EBL resists are made needless.

A fresh review "Ice lithography for 3-D nanofabrication" by Prof. Min Qiu at Westlake University is published in Science Bulletin. In this review, the authors present current status and future perspectives of ice lithography (IL). Different ice resists and IL instrument design are also introduced. Special emphasis is placed on advantages of IL for 3-D nanofabrication.

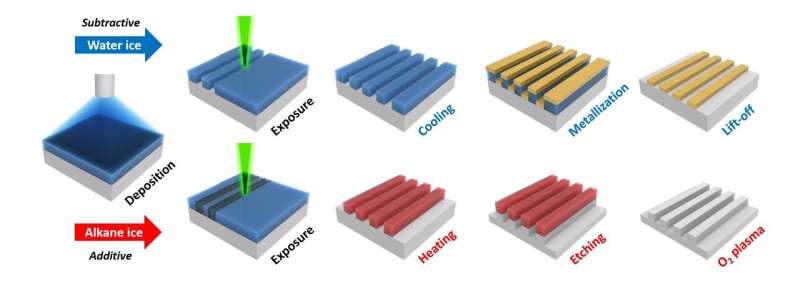

The IL technology was first proposed by the Nanopore group at Harvard University in 2005. Water ice is the first identified ice resist for IL, and it is still the only one positive-tone lithography resist so far. As shown in Fig.1, water ice is easily removed within the electron-beam exposure area. Organic ice condensed from simple organic molecules, such as alkanes, demonstrates a negative-resist-like capability, which means only exposed patterns remain on the substrate after heating the sample to room temperature.

IL research is still in its infancy, and this method has already exhibited great advantages in efficient 3-D nanofabrication. Different from spin coating of EBL resists, ice resists are able to coat all accessible freezing surfaces of the sample during ice deposition. Therefore, IL can process samples with non-flat and irregular surfaces, such as patterning on AFM probes, and pattern on a tiny and fragile nanostructure, such as suspended single-walled carbon nanotubes. Benefiting from the very low sensitivity of water ice, IL allows in situ observing nanostructures under the ice resist through SEM imaging. This feature not only improves the alignment accuracy but also simplifies the processing steps in fabricating 3-D layered nanostructures.

As cutting-edge instrument research and development is essential for advancing the IL technology, this review finally discusses the evolution of IL instruments and provides a clear guidance on the construction of a dedicated IL instrument. With the discovery of new functional ice resists in future, more cutting-edge and interdisciplinary researches are expected to exploit the potentials of IL.

More information: Ding Zhao et al, Ice lithography for 3D nanofabrication, Science Bulletin (2019). DOI: 10.1016/j.scib.2019.06.001

Provided by Science China Press