Metal too 'gummy' to cut? Draw on it with a Sharpie or glue stick, science says

Your everyday permanent markers, glue sticks and packing tape may offer a surprisingly low-tech solution to a long-standing nuisance in the manufacturing industry: Making soft and ductile, or so-called "gummy" metals easier to cut.

What makes inks and adhesives effective isn't their chemical content, but their stickiness to the surface of any gummy metal such as nickel, aluminum, stainless steels or copper, researchers at Purdue University and the University of West Florida find in a study recently published in Physical Review Applied.

These adhesives help achieve a smoother, cleaner and faster cut than current machining processes, impacting applications ranging from the manufacturing of orthopedic implants and surgical instruments to aerospace components.

"A wide range of products rely on the machining of gummy metals. These could be something we use every day, such as the valve in a sink faucet, or something more critical like a compressor part in the jet engine of an airplane," said James Mann, assistant professor of mechanical engineering at the University of West Florida and Purdue alumnus.

If a significant improvement can be made to the "machinability" of gummy metals or alloys—which is how well they cut, drill or grind—then there is potential to lower the cost of products, improve their performance or enable new and improved designs.

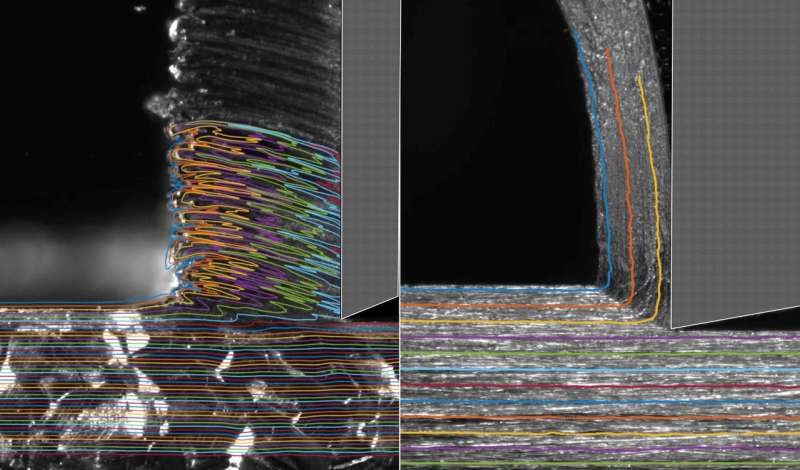

"Gummy metals characteristically deform in a very wiggly manner," said Srinivasan Chandrasekar, Purdue professor of industrial engineering. "This wiggly flow involves significant energy consumption, which means that these metals require more force to machine than even some hard metals. We needed to find a way to suppress this wiggly flow."

Getting rid of the wiggles means that the metal now tends to act more like a brittle ceramic or glass in the spot where it needs to be cut.

One well-known way to make the gummy metal brittle is by coating it with a suitable liquid metal, such as gallium in the case of aluminum. Liquid metals like these, however, tend to work too well; diffusing through the surface and causing the whole metal to crumble into a powder.

"This makes the metal being machined unusable," Chandrasekar said.

Other attempts met with limited success tended to be either toxic or result in tears and cracks on the machined surface. The researchers then began to explore other benign chemical media that would cut cleaner.

Marking with ink or attaching any adhesive on the metal's surface dramatically reduced the force of cutting without the whole metal falling apart, leaving a clean cut in seconds. The quality of the machined surface also greatly improved.

Stickiness didn't initially stand out as a solution that permanent markers, glue sticks and tape have in common.

"We looked at the chemical ingredients of the permanent ink, isolated each of those on the metal's surface, and there was no noticeable effect," said Anirudh Udupa, lead author on the study and a postdoctoral researcher in Purdue's School of Industrial Engineering. "So we realized that it's not a particular chemical but the ink itself sticking to the metal through a physical adsorption mechanism."

The Sharpie and adhesives also appeared to work on many gummy metals, regardless of the cutting tool.

"In hindsight, we can tell you why certain things weren't successful in previous work. It all comes back to the existence of this wiggly flow," said Koushik Viswanathan, Purdue postdoctoral researcher in industrial engineering. "Some people might have been trying to cut copper, for example, that was in the hard state rather than in the soft state."

To the researchers' knowledge, using permanent markers, glues or tape to make gummy metals easier to machine does not pose any environmental hazards.

Next, Chandrasekar's group will be assessing the degree of stickiness that works best for cutting gummy metals and exploring ways to advance the application of this technology into industrial practice.

More information: Anirudh Udupa et al, Material-Independent Mechanochemical Effect in the Deformation of Highly-Strain-Hardening Metals, Physical Review Applied (2018). DOI: 10.1103/PhysRevApplied.10.014009

Provided by Purdue University