Breakthrough in industrial CO2 usage

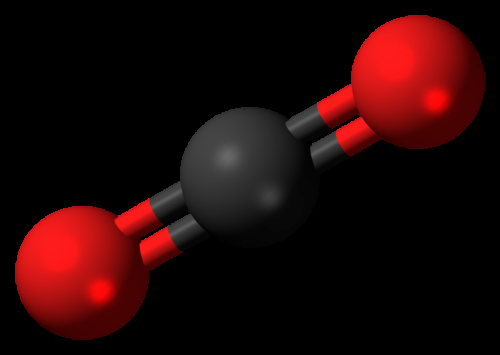

Professor Arne Skerra of the Technical University of Munich (TUM) has succeeded for the first time in using gaseous CO2 as a basic material for the production of a chemical mass product in a biotechnical reaction. The product is methionine, which is used as an essential amino acid, particularly in animal feed, on a large scale. This newly developed enzymatic process could replace its current petrochemical production. The results have now been published in the journal Nature Catalysis.

The industrial production of methionine from petrochemical source materials is currently done via a six-step chemical process that requires highly toxic hydrogen cyanide, among other substrates. In 2013, Evonik Industries, one of the world's largest manufacturers of methionine, invited university researchers to propose new processes for making the substance safer to produce. Methional, which occurs in nature as a degradation product of methionine, is formed as a facile intermediate during the conventional process.

"Based on the idea that methionine in microorganisms is degraded by enzymes to methional with the release of CO2, we tried to reverse this process," explains Professor Arne Skerra from the Department of Biological Chemistry at TUM, "because every chemical reaction is in principle reversible, while often only with the extensive use of energy and pressure." Skerra participated in the call for proposals with this idea, and Evonik awarded the concept and supported the project.

Supported by postdoctoral researcher Lukas Eisoldt, Skerra began to determine the parameters for the manufacturing process and for producing the necessary biocatalysts (enzymes). The scientists conducted initial experiments and determined the CO2 pressure which would be needed to produce methionine from methional in a biocatalytic process. Surprisingly, an unexpectedly high yield resulted even at a relatively low pressure—approximately corresponding to the one in a car tire of approximately two bars. Based upon the achievements after just one year, Evonik extended the funding, and now the team, reinforced by the Ph.D. student Julia Martin, investigated the biochemical background of the reaction and optimized the enzymes involved using protein engineering.

More efficient than photosynthesis

After several years of work, not only was it possible to improve the reaction on a laboratory scale to a yield of 40 percent, but also to elucidate the theoretical background of the biochemical processes. "Compared to the complex photosynthesis, in which nature also biocatalytically incorporates CO2 into biomolecules as a building block, our process is highly elegant and simple," reports Arne Skerra. "Photosynthesis uses 14 enzymes and has a yield of only 20 percent, while our method requires just two enzymes."

In the future, the basic principle of this novel biocatalytic reaction can serve as a model for the industrial production of other valuable amino acids or precursors for pharmaceuticals. Meanwhile, Professor Skerra's team will refine the process, which has been patented, using protein engineering so that it will become suitable for large-scale application.

This could be the first time that there is a biotechnological manufacturing process using gaseous CO2 as an immediate chemical precursor. Up to now, attempts to recycle the greenhouse gas, which is a major contributor to climate change, have failed due to the extremely high energy required to do so.

More information: Julia Martin et al, Fixation of gaseous CO2 by reversing a decarboxylase for the biocatalytic synthesis of the essential amino acid l-methionine, Nature Catalysis (2018). DOI: 10.1038/s41929-018-0107-4

Journal information: Nature Catalysis

Provided by Technical University Munich