Team develops highly stretchable hydrogels for high resolution multimaterial 3-D printing

Hydrogels, hydrophilic networks of polymeric chains capable of retaining a large amount of water, have been widely used in a variety of applications. Recent advances in highly stretchable hydrogels have extended their applications into the fields of soft robotics, transparent touch panels and other applications requiring large deformation.

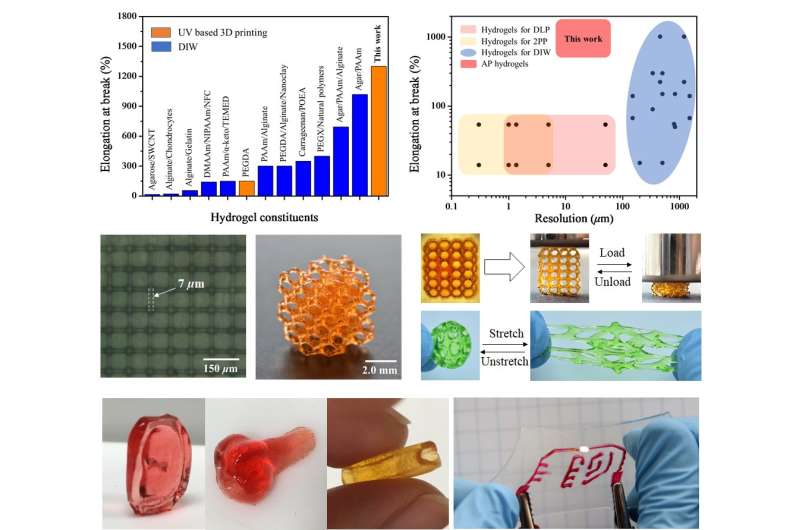

However, traditional fabrication methods, which mainly rely on molding and casting, confine the scope of applications due to the limited geometric complexity and the relatively low fabrication resolution. Along with recent rapid developments in 3-D printing, various attempts have also been made to use 3-D printing to fabricate hydrogel structures with complex geometries including vascular networks, porous scaffolds, meniscus substitutes and others. Nevertheless, existing 3-D printed hydrogels do not have high printing resolution, high geometric complexity as well as high stretchability, which makes them unsuitable for many applications.

Recently, researchers from the Singapore University of Technology and Design (SUTD) Digital Manufacturing and Design (DManD) Centre and the Hebrew University of Jerusalem (HUJI) have developed a family of highly stretchable and UV curable hydrogels that can be stretched by up to 1300%, and are suitable for UV curing based 3-D printing techniques. These have been adopted to fabricate hydrogel structures that require high printing resolution and high geometric complexity. Details of this work appeared in the April 2018 issue of Journal of Materials Chemistry B and it was also featured on the front cover.

"We have developed the most stretchable 3-D printed hydrogel sample in the world," said Assistant Professor Qi (Kevin) Ge from SUTD's Science and Math Cluster, who is one of the co-leaders of this project. He added: " The printed hydrogel sample can be stretched by up to 1300%. At the same time, the compatibility of these hydrogels with digital light processing-based 3-D printing technology allows us to fabricate hydrogel 3-D structures with resolutions up to 7 μm and complex geometries."

"The printed stretchable hydrogels show an excellent biocompatibility, which allows us to directly 3-D print biostructures and tissues. The great optical clarity of these hydrogels offers the possibility of 3-D printing contact lenses. More importantly, these 3-D printable hydrogels can form strong interfacial bonding with commercial 3-D printing elastomers, which allows us to directly 3-D print hydrogel-elastomer hybrid structures such as a flexible electronic board with a conductive hydrogel circuit printed on an elastomer matrix," said Professor Ge.

"Overall, we believe the highly stretchable and UV curable hydrogels, together with the UV curing based 3-D printing techniques, will significantly enhance the capability of fabricating biostructures and tissue, contact lenses, flexible electronics, and many other applications," said Professor Shlomo Magdassi who is a co-leader of this project at HUJI.

More information: Biao Zhang et al, Highly stretchable hydrogels for UV curing based high-resolution multimaterial 3D printing, Journal of Materials Chemistry B (2018). DOI: 10.1039/C8TB00673C

Provided by Singapore University of Technology and Design