Method assembles cellulose nanofibres into a material stronger than spider silk

Researchers in Sweden have produced a bio-based material that is reported to surpass the strength of all known bio-based materials whether fabricated or natural, including wood and spider silk.

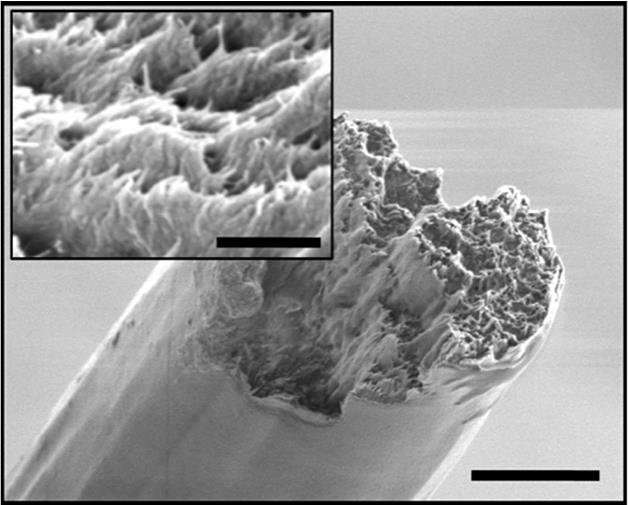

Working with cellulose nanofibre (CNF), the essential building block of wood and other plant life, the researchers report that they have overcome the difficulty in translating the incredible mechanical properties of these nanofibres into larger, lightweight materials for use in airplanes, cars, furniture and other products.

"The bio-based nanocellulose fibres fabricated here are 8 times stiffer and have strengths higher than natural dragline spider silk fibres, generally considered to be the strongest bio-based material," says corresponding author Daniel Söderberg, researcher at KTH Royal Institute of Technology. "The specific strength is exceeding that of metals, alloys, ceramics and E-glass fibres."

Published in the journal of American Chemical Society (ACS Nano), the study describes a new method that mimics nature's ability to arrange cellulose nanofibres into almost perfect macroscale arrangements.

The reported progress results from the development of insights into the way physics controls structuring of components, such as CNF, at the nanoscale during fabrication.

This understanding enabled a new process, which involves controlling the flow of nanofibres suspended in water in a 1 mm wide channel milled in stainless steel. Connecting flows of deionized water and low pH water help align the nanofibres in the right direction and enable the supramolecular interactions between CNFs to self-organize into a well-packed state where they are joined together.

"This discovery is made possible by understanding and controlling the key fundamental parameters essential for perfect nanostructuring, such as particle size, interactions, alignment, diffusion, network formation and assembly," Söderberg says.

Söderberg says the study opens the way for developing nanofibre material that can be used for larger structures while retaining the nanofibres' tensile strength and ability to withstand mechanical load. The process can also be used to control nanoscale assembly of carbon tubes and other nano-sized fibres.

Measurements of the material were reported for tensile stiffness, 86 gigapascals (GPa), and for tensile strength, 1.57 GPa.

More information: Near-Perfect Assembly of Nanoscale Building Blocks into Macroscopic Materials ACS Nano, dx.doi.org/10.1021/acsnano.8b01084

Journal information: ACS Nano

Provided by KTH Royal Institute of Technology