New electric vehicle technology packs more punch in smaller package

Using 3-D printing and novel semiconductors, researchers at the Department of Energy's Oak Ridge National Laboratory have created a power inverter that could make electric vehicles lighter, more powerful and more efficient.

At the core of this development is wide bandgap material made of silicon carbide with qualities superior to standard semiconductor materials. Power inverters convert direct current into the alternating current that powers the vehicle. The Oak Ridge inverter achieves much higher power density with a significant reduction in weight and volume.

"Wide bandgap technology enables devices to perform more efficiently at a greater range of temperatures than conventional semiconductor materials," said ORNL's Madhu Chinthavali, who led the Power Electronics and Electric Machinery Group on this project. "This is especially useful in a power inverter, which is the heart of an electric vehicle."

Specific advantages of wide bandgap devices include: higher inherent reliability; higher overall efficiency; higher frequency operation; higher temperature capability and tolerance; lighter weight, enabling more compact systems; and higher power density.

Additive manufacturing helped researchers explore complex geometries, increase power densities, and reduce weight and waste while building ORNL's 30-kilowatt prototype inverter.

"With additive manufacturing, complexity is basically free, so any shape or grouping of shapes can be imagined and modeled for performance," Chinthavali said. "We're very excited about where we see this research headed."

Using additive manufacturing, researchers optimized the inverter's heat sink, allowing for better heat transfer throughout the unit. This construction technique allowed them to place lower-temperature components close to the high-temperature devices, further reducing the electrical losses and reducing the volume and mass of the package.

Another key to the success is a design that incorporates several small capacitors connected in parallel to ensure better cooling and lower cost compared to fewer, larger and more expensive "brick type" capacitors.

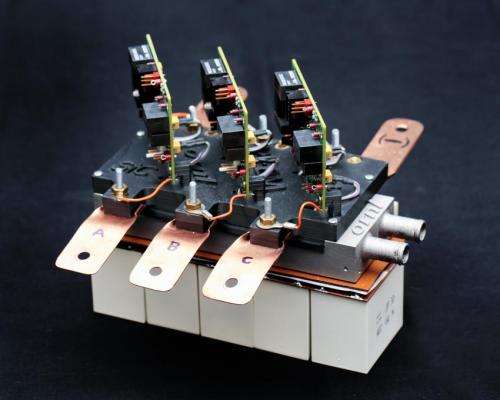

The research group's first prototype, a liquid-cooled all-silicon carbide traction drive inverter, features 50 percent printed parts. Initial evaluations confirmed an efficiency of nearly 99 percent, surpassing DOE's power electronics target and setting the stage for building an inverter using entirely additive manufacturing techniques.

Building on the success of this prototype, researchers are working on an inverter with an even greater percentage of 3-D printed parts that's half the size of inverters in commercially available vehicles. Chinthavali, encouraged by the team's results, envisions an inverter with four times the power density of their prototype.

Provided by Oak Ridge National Laboratory