Experiment enters next stage at new Idaho hot cell

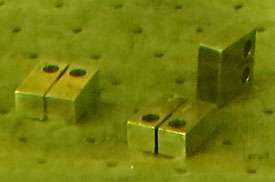

To the average eye, the experimental specimens don't look like much: silver-colored squares about the size of a domino. But the samples represent several big milestones for Idaho National Laboratory, the Department of Energy and the U.S. nuclear energy industry.

The irradiated "compact tension" specimens are among the largest INL scientists have worked with and are the first to undergo analysis in a specialized test rig at INL. Plus, they're part of a first-of-its-kind collaboration through the DOE's Advanced Test Reactor National Scientific User Facility (ATR NSUF).

The pair of nickel-based alloy test specimens were irradiated, then loaded into new test rigs in the newest research hot cells at INL's Materials and Fuels Complex (MFC). The accomplishment marked the first use of an important new research capability at the nation's lead nuclear energy research laboratory. The loading of the experimental specimens also marked the next stage in a series of experiments with research partners at the Electric Power Research Institute (EPRI) – a nonprofit research, development and demonstration organization for the electric utility industry.

"This experiment will tell us how fast a flaw will propagate under the conditions that exist inside a reactor. It will give us insight into how long an irradiated material can be expected to withstand those conditions," said Dr. Sebastien Teysseyre, an INL principal investigator who is researching the material. "These tests are critical because they will help provide the basis for criteria used by plant operators and regulators as they work to maintain the high safety and operability standards of current nuclear power plants over time."

Stress corrosion cracking, or SCC, is the study of crack formation in a given material under punishing environmental conditions such as temperature, corrosivity and stress. Studying the SSC properties of a desired material is crucial for material scientists and engineers. A host of environmental factors can change a material's susceptibility to SCC, and therefore, its suitability for a given purpose. For example, a thorough understanding of SCC properties of various steel alloys is critical for choosing the right ones to use for uses such as bridge girders or roof beams – or the structural and cladding materials used in nuclear reactors.

One important environmental factor in the nuclear industry is the effect of irradiation, which makes gathering SCC data much more challenging. Irradiation-Assisted Stress Corrosion Cracking (IASCC) studies help engineers understand the properties of metal and other materials in the environments where they will be used. Studying IASCC requires capabilities for which INL is uniquely suited, thanks to the proximity of the Advanced Test Reactor and the post-irradiation examination capabilities at MFC.

The IASCC test rigs in MFC's newest hot cells allow researchers to gather data on the growth of cracks in highly radioactive compact tension (CT) specimens within shielded hot cells. The rigs enable researchers to measure a specimen's response to mechanical stresses like tension combined with the effects of water chemistry and temperature, with the "irradiation assist" coming from carefully selected levels of exposure to the neutron flux available in ATR.

The samples for this first experiment are a nickel-based alloy commonly used in reactor structural components. It is just one of several materials for which researchers seek to evaluate how irradiated metal alloys behave in reactor environments. These first experiments are taking place as part of a cooperative agreement between DOE's ATR NSUF and EPRI.

"Similar to how the intense neutron flux of the ATR can simulate the irradiation effects a reactor places on a fuel or material sample, the IASCC test rigs give us the ability to simulate the other physical effects inside a reactor, like pressure and water chemistry, on highly-irradiated specimens," said Mark Henry, MFC research director. "The data we can gather from these experiments will be invaluable for extending the life of our current fleet of reactors, and for eventually selecting materials for newer ones that are even more safe and more efficient."

What is ATR NSUF?

Since 2007, the Advanced Test Reactor (ATR) National Scientific User Facility (NSUF) has opened to external researchers ("users") an impressive suite of nuclear materials and fuels research capabilities located across the country, including unique irradiation and examination facilities at Idaho National Laboratory and a variety of capabilities available at 11 partner facilities. In addition to the research described here, two more industry-led ATR NSUF projects are underway for the U.S. Nuclear Regulatory Commission and Atomic Energy of Canada Limited. For more information, visit atrnsuf.inl.gov.

Provided by Idaho National Laboratory