Transforming roofs from wasted space to energy source

(PhysOrg.com) -- A transparent thin film barrier used to protect flat panel TVs from moisture could become the basis for flexible solar panels that would be installed on roofs like shingles.

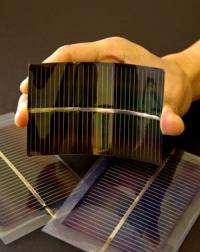

The flexible rooftop solar panels - called building-integrated photovoltaics, or BIPVs - could replace today's boxy solar panels that are made with rigid glass or silicon and mounted on thick metal frames. The flexible solar shingles would be less expensive to install than current panels and made to last 25 years.

"There's a lot of wasted space on rooftops that could actually be used to generate power," said Mark Gross, a senior scientist at the Department of Energy's Pacific Northwest National Laboratory. "Flexible solar panels could easily become integrated into the architecture of commercial buildings and homes. Solar panels have had limited success because they've been difficult and expensive to install."

Researchers at PNNL will create these flexible panels by adapting a film encapsulation process currently used to coat flat panel displays that use organic light-emitting diodes, or OLEDs. The work is made possible by a Cooperative Research and Development Agreement recently penned between Vitex Systems and Battelle, which operates PNNL for the federal government.

PNNL researchers developed the thin film technology in the 1990s. At the time, the lab's team investigated 15 possible applications, including solar power. Vitex licensed the technology from Battelle in 2000 and focused its initial efforts on developing the ultra-barrier films for flat-panel displays. Now PNNL and Vitex are taking a hard second look at solar power.

The encapsulation process and the ultra-barrier film - called Barix™ Encapsulation and Barix™ Barrier Film, respectively - are already proven and effective moisture barriers. But researchers need to find a way to apply the technology to solar panels, which are also called photovoltaics, or PVs. Under the agreement, researchers will create low-cost flexible barrier films and evaluate substrate materials for solar panels. Both the film and substrate must be able to survive harsh ultraviolet rays and natural elements like rain and hail for 25 years.

The agreement also calls for researchers to develop a manufacturing process for the flexible panels that can be readily adapted to large-scale production. If successful, this process will reduce solar panel manufacturing costs to less than $1 per watt of power, which would be competitive with the 10 cents per kilowatt-hour that a utility would charge.

"Vitex is proud to continue its long, successful relationship with PNNL," said Martin Rosenblum, Vitex's vice president of operations and engineering. "Vitex is excited to further its Barix technology's proven barrier performance for photovoltaics toward mass manufacturing. Together, we look forward to creating a product that will help alleviate America's dependence on foreign oil and increase America's access to an abundant renewable energy source - the sun."

Battelle, which is the majority shareholder of Vitex, is optimistic that this research agreement will contribute to a new way of generating solar power. Battelle recently increased its investment in Vitex for new state-of-the-art thin film encapsulation equipment and expanded its intellectual property portfolio.

"We're confident that Vitex will be uniquely positioned to help meet the demand for flexible solar panels, OLED displays and lighting that should rise along with the economy," said Martin Inglis, Battelle's chief financial officer.

Provided by Pacific Northwest National Laboratory (news : web)