Screen-printed solar cells

Members of the Fraunhofer Institute for Solar Energy Systems ISE are traveling to Tokyo with bulky luggage these days. Their destination is Nanotech 2008, the world’s largest trade fair for nanotechnology. Their solar module, which they will be presenting in the BMBF marketing campaign ‘Nanotech Germany’, is the size and shape of a door: two meters high and sixty centimeters wide.

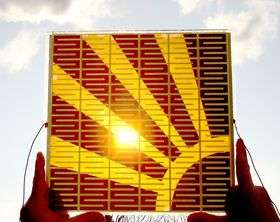

The key component of the new modules is an organic dye which in combination with nanoparticles converts sunlight into electricity. Due to the small size of the nanoparticles, the modules are semi-transparent. This aspect makes them well suited for façade integration. The solar module prototype manufactured by the researchers at Fraunhofer ISE is amber in color.

It is possible, however, to produce the modules in other colors, or even to print images or text on the module so that it serves as a decorative element. These design options open up an entirely new range of possible applications. Instead of mounting the solar module on the roof of a building, the electricity producer could be integrated in the glass façade. Used in this way, the new technology not only prohibits direct sunlight from entering the building interior but also generates electricity at the same time.

“We don’t see the dye solar cell as being a rival to the conventional silicon cell,” says Fraunhofer ISE physicist Andreas Hinsch. The module prototypes only achieve an efficiency of four percent, which is not sufficient for rooftop applications in comparison to the performance of crystalline silicon solar cells. On the other hand, dye solar cells have a clear advantage when it comes to façade integration.

The wafer-thin electricity-generating film, which lies between two glass panes, is produced from nanoparticles and applied using screen printing technique. This technique makes it possible to integrate any desired image on the module. A glass facade made of this material can be given a decorative and promotionally effective design, such as a colorful company logo, and delivers electricity into the bargain.

The dye solar module is still a prototype. The Fraunhofer researchers have developed it together with industry partners in the ColorSol project funded by the German Federal Ministry of Education and Research BMBF.

One particular challenge posed by the new technology is that the narrow gap between the two glass panes must be hermetically sealed so that no air can get in and destroy the reactive substances inside. The Fraunhofer experts have come up with a special solution to this problem. Instead of using polymeric glue like their competitors, they have decided to work with glass frit. To this end, glass powder is screen-printed onto the panes, and fuses with them at a temperature of around 600 degrees Celcius.

Fatigue tests under various weather conditions have shown that the solar cells still function properly even after several thousand hours. The long-term stability as such, however, has yet to be officially certified.

Source: Fraunhofer-Gesellschaft