Spintronic thermoelectric power generators: A step towards energy efficient electronic devices

(Phys.org) —Imagine a computer so efficient that it can recycle its own waste heat to produce electricity. While such an idea may seem far-fetched today, significant progress has already been made to realize these devices. Researchers at the Nanostructured Materials Research Laboratory at the University of Utah have fabricated spintronics-based thin film devices which do just that, i.e. convert even minute waste heat into useful electricity.

"As electronic devices enter the nano-size regime, the problem of heat generation is becoming more and more severe," says University of Utah Materials Scientist Ashutosh Tiwari, who led the research published online Friday, March 21 in the Nature publishing group's journal Scientific Reports.

"Our spintronic-based thermoelectric devices work at room temperature and don't require the continuous application of an external magnetic field," Tiwari says. "Most of the spintronic thermoelectric devices in earlier studies required the continuous application of a magnetic field to keep the device magnetized."

"Spintronics is a new branch of electronics which utilizes both the charge as well as the spin of electrons," says Tiwari.

"Tiwari conducted the research with graduate students Gene Siegel, Megan Campbell Prestgard, and Shiang Teng. The study was funded by the U.S. National Science Foundation's Condensed Matter Physics Program, Sensors and Sensing Systems Program, and the University of Utah's Materials Research Science and Engineering Center."

"The most important and fascinating aspect of our study is that these devices are not made of traditional thermoelectric materials which, when heated, generate a voltage simply because of the movement of charge carriers. This, known as the Seebeck effect, has a fundamental limitation," says Tiwari. "Specifically, for achieving heat-to-electricity conversion efficiencies which are acceptable for practical applications, the electrical conductivity of the thermoelectric material should be maximized while its thermal conductivity should be simultaneously minimized. These two requirements are contradictory."

He adds, "Our spintronic-based devices function on an altogether different concept known as spin-caloritronics. Here, thermal and electrical transport occurs in different parts of the device and hence these devices are not plagued by the problems encountered by their traditional counterparts."

Experiment

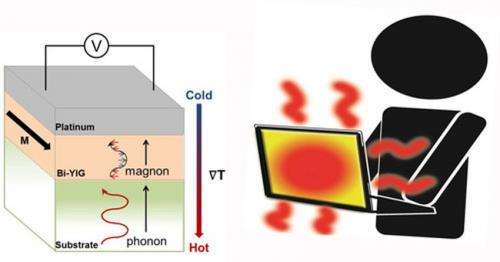

For making spintronic thermoelectric devices, Utah researchers deposited thin films of a material know as bismuth-doped YIG (Bi-YIG) using a 25 nanosecond pulsed laser. Over the Bi-YIG film, a 10 nm thick layer of platinum was deposited using electron beam evaporation. The prepared bi-layer structure was kept in a magnetic field for a few minutes to magnetically polarize the Bi-YIG film. After this, the external magnetic field was removed and a temperature gradient was applied across the bilayer. This temperature difference leads to a current of low-lying excitations of localized spins, known as magnons, in the Bi-YIG. "When this magnon current enters into the platinum layer, it is converted into a charge voltage through a process known as the inverse spin Hall effect," explains Gene Siegel, first author of the paper.

The researchers' trick was to generate a very large roughness on the surface of the Bi-YIG films by using very high energy density laser pulses. Rough surfaces resulted in very large stray fields, which gave rise to large magnetic coercivity in the films. "Because of the large coercivity, once these devices are magnetized they remain magnetized and don't require any external field for operation," says Siegel.

"Our experimental findings are in excellent agreement with the predictions of the magnon transport theory," says Tiwari.

"Tiwari's group's research opens the doors for the development of spin-driven thermoelectrics which can turn waste heat into electricity, and make efficient electronic devices," says Ajay Nahata, Director of the University of Utah's NSF MRSEC on Next Generation Materials for Plasmonics & Organic Spintronics.

More information: Siegel, G., Prestgard, M.C., Teng, S. & Tiwari, A. Robust longitudinal spin-Seebeck effect in Bi-YIG thin films. Sci. Rep. 4, 4429; DOI: 10.1038/srep04429 (2014).

Journal information: Scientific Reports

Provided by University of Utah