October 31, 2013 report

Researchers discover nanoparticles can be fabricated using Leidenfrost drops (w/ Video)

(Phys.org) —A team of researchers from several research institutions in Germany has found that certain types of nanoparticles can be created using levitated drops of heated water—Leidenfrost drops. In their paper published in the journal Nature Communications, the team describes how they created metal polymer hybrid foams and other nanoparticles using nothing more than water on a heated substrate.

Most everyone has seen Leidenfrost drops in action, they occur when dumping a small amount of water into an already heated pan—the drops that form slide around as if there is no friction due to the steam that builds up beneath them. In this new effort, the researchers noted that not only does water turn to steam in Leidenfrost drops but it appears that positive ions gather in that steam leaving negative ions to collect in the liquid above. If melted metal is added to the mix, its positive ions are attracted to the negative ions in the liquid where they react and solidify into certain types of nanoparticles.

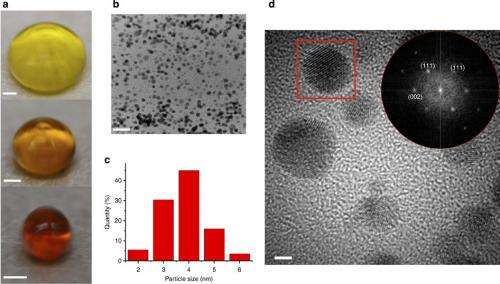

Using this technique the team found they were able to create nanoporous black gold as well as different types of nanoparticle based foams and also nanoparticle coatings that adhere to a three-dimensional substrate—all without using any toxic chemicals. Researchers have been searching for a way to create such materials in new ways that don't result in toxic byproducts. Conventional methods rely on the use of a variety of toxic chemicals to cause the desired reactions to come about. That in turn leads to environmental problems as well as concern about the toxicity of the nanomaterials themselves. The process using Leidenfrost drops, on the other hand, is as clean as it gets, the researchers report, with no need for reducing agents—the reactions occur in the heated drops without any other mixing either—leading the researchers to describe the technique as "green chemistry." The end result is a much cleaner way to make nanoparticles, which is good news as scientists have been discovering new uses for them in a large variety of products. The researchers believe the nanoparticles they have created thus far might one day be used in medical or electrical components.

More information: Green chemistry and nanofabrication in a levitated Leidenfrost drop, Nature Communications 4, Article number: 2400 DOI: 10.1038/ncomms3400

Abstract

Green nanotechnology focuses on the development of new and sustainable methods of creating nanoparticles, their localized assembly and integration into useful systems and devices in a cost-effective, simple and eco-friendly manner. Here we present our experimental findings on the use of the Leidenfrost drop as an overheated and charged green chemical reactor. Employing a droplet of aqueous solution on hot substrates, this method is capable of fabricating nanoparticles, creating nanoscale coatings on complex objects and designing porous metal in suspension and foam form, all in a levitated Leidenfrost drop. As examples of the potential applications of the Leidenfrost drop, fabrication of nanoporous black gold as a plasmonic wideband superabsorber, and synthesis of superhydrophilic and thermal resistive metal–polymer hybrid foams are demonstrated. We believe that the presented nanofabrication method may be a promising strategy towards the sustainable production of functional nanomaterials.

Journal information: Nature Communications

© 2013 Phys.org