July 9, 2013 report

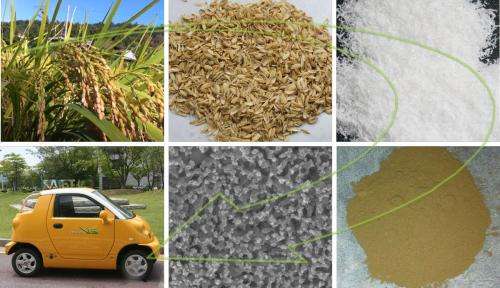

Phone and car batteries could use silicon made from rice

(Phys.org) —Silicon is in great demand. When used in lithium-ion batteries (LIBs), which power smartphones and electric and hybrid cars, silicon anodes have a much greater theoretical capacity than conventional graphite anodes. However, anodes made from silicon alloys suffer from capacity fading, which makes them inefficient. Jang Wook Choi and his colleagues at several Korean universities have found a way to convert silica from rice husks, a cheap and widely available resource, into silicon for use in high-performance LIBs. This silicon has a naturally occurring nanoporous structure that prevents capacity fading. The research appears in the Proceedings of the National Academy of Sciences.

Rice is a staple food for more than one third of the world's population. Every year, rice growers produce about 422 million metric tons. Rice husks, a waste product produced during cultivation, make up about 20 percent of this. Because these husks are very abrasive, agricultural manufacturers use them in cheap items, such as fertilizer additives, stockbreeding rugs and bed soil, which take advantage of this quality.

Choi and his team believe that rice husks could have a more valuable use. They contain large amounts of silica, which engineers can convert to silicon for use in LIBs. Silica comprises between 15 and 20 percent of a rice husk's weight. This silica has evolved to be nanoporous, so that air and moisture can enter rice kernels but bacteria and insects cannot.

The researchers extracted pure silicon from rice husk silica by adding acid and heat to remove metallic impurities and organic components and then using magnesium to reduce the silica to silicon. This treatment preserved the three-dimensional porous nanostructure. They then coated this silicon with carbon and used it in anodes in lithium coin cells.

Choi's team found that these anodes were more efficient than anodes made with silicon alloys. The anodes made from rice husk silicon had high coulombic efficiency and excellent discharge capacity retention, which the team attributed to the interconnected porous structure of the silicon enabling the formation of stable solid electrolyte interfaces (SEIs). In comparison, anodes made from silicon alloys suffer from capacity fading because their high volume change, which can reach 300%, causes the alloys to fracture and unstable SEIs to form.

The researchers suggest that silicon extracted from rice husks could help meet the increasing demand for silicon in batteries used to run portable electronic devices and hybrid electric vehicles. This would allow a waste product from one of the world's most popular crops to contribute to the development of advanced technologies.

More information: Recycling rice husks for high-capacity lithium battery anodes, PNAS, Published online before print July 8, 2013, doi: 10.1073/pnas.1305025110

Abstract

The rice husk is the outer covering of a rice kernel and protects the inner ingredients from external attack by insects and bacteria. To perform this function while ventilating air and moisture, rice plants have developed unique nanoporous silica layers in their husks through years of natural evolution. Despite the massive amount of annual production near 108 tons worldwide, so far rice husks have been recycled only for low-value agricultural items. In an effort to recycle rice husks for high-value applications, we convert the silica to silicon and use it for high-capacity lithium battery anodes. Taking advantage of the interconnected nanoporous structure naturally existing in rice husks, the converted silicon exhibits excellent electrochemical performance as a lithium battery anode, suggesting that rice husks can be a massive resource for use in high-capacity lithium battery negative electrodes.

Journal information: Proceedings of the National Academy of Sciences

© 2013 Phys.org