Splitting the sea: Turning ocean water into hydrogen fuel

(Phys.org) —University of Wollongong scientists have developed a novel way to turn sea water into hydrogen, for a sustainable and clean fuel source.

Using this method, as little as five litres of sea water per day would produce enough hydrogen to power an average-sized home and an electric car for one day.

The research team at UOW's Australian Research Council Centre of Excellence for Electromaterials Science (ACES) have developed a light-assisted catalyst that requires less energy input to activate water oxidation, which is the first step in splitting water to produce hydrogen fuel.

A major limitation with current technologies is that the oxidation process needs a higher energy input, which rules out using abundant sea water because it produces poisonous chlorine gas.

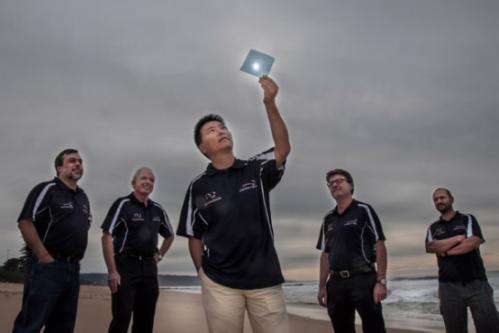

The research team, led by Associate Professor Jun Chen and Professor Gerry Swiegers, have produced an artificial chlorophyll on a conductive plastic film that acts as a catalyst to begin splitting water.

The results were recently published in the journal Chemical Science.

Lead author, Associate Professor Jun Chen, said the flexible polymer would mean it could be used in a wider range of applications and it is more easily manufactured than metal semiconductors.

"The system we designed, including the materials, gives us the opportunity to design various devices and applications using sea water as a water-splitting source.

"The flexible nature of the material also provides the possibility to build portable hydrogen-producing devices."

The development brings UOW's energy research a step closer to creating an artificial leaf-like device that can efficiently produce hydrogen.

ACES Executive Research Director Professor Gordon Wallace said: "In today's world the discovery of high performance materials is not enough".

"This must be coupled with innovative fabrication to provide practical high-performance devices and this work is an excellent example of that," he said.

More information: pubs.rsc.org/en/Content/Articl … g/2013/SC/c3sc50812a

Journal information: Chemical Science

Provided by University of Wollongong