New carbon films improve prospects of solar energy devices

New research by Yale University scientists helps pave the way for the next generation of solar cells, a renewable energy technology that directly converts solar energy into electricity.

In a pair of recent papers, Yale engineers report a novel and cost-effective way to improve the efficiency of crystalline silicon solar cells through the application of thin, smooth carbon nanotube films. These films could be used to produce hybrid carbon/silicon solar cells with far greater power-conversion efficiency than reported in this system to date.

"Our approach bridges the cost-effectiveness and excellent electrical and optical properties of novel nanomaterials with well-established, high efficiency silicon solar cell technologies," said André D. Taylor, assistant professor of chemical and environmental engineering at Yale and a principal investigator of the research.

The researchers reported their work in two papers published in December, one in the journal Energy and Environmental Science and one in Nano Letters. Mark A. Reed, a professor of electrical engineering and applied physics at Yale, is also a principal investigator.

Silicon, an abundant element, is an ideal material for solar cells because its optical properties make it an intrinsically efficient energy converter. But the high cost of processing single-crystalline silicon at necessarily high temperatures has hindered widespread commercialization.

Organic solar cells—an existing alternative to high-cost crystalline silicon solar cells—allow for simpler, room-temperature processing and lower costs, researchers said, but they have low power-conversion efficiency.

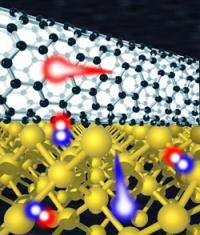

Instead of using only organic substitutes, the Yale team applied thin, smooth carbon nanotube films with superior conductance and optical properties to the surface of single crystalline silicon to create a hybrid solar cell architecture. To do it, they developed a method called superacid sliding.

As reported in the papers, the approach allows them to take advantage of the desirable photovoltaic properties of single-crystalline silicon through a simpler, low-temperature, lower-cost process. It allows for both high light absorption and high electrical conductivity.

"This is striking, as it suggests that the superior photovoltaic properties of single-crystalline silicon can be realized by a simple, low-temperature process," said Xiaokai Li, a doctoral student in Taylor's lab and a lead author on both papers. "The secret lies in the arrangement and assembly of these carbon nanotube thin films,"

In previous work, Yale scientist successfully developed a carbon nanotube composite thin film that could be used in fuel cells and lithium ion batteries. The recent research suggests how to extend the film's application to solar cells by optimizing its smoothness and durability.

"Optimizing this interface could also serve as a platform for many next-generation solar cell devices, including carbon nanotube/polymer, carbon/polymer, and all carbon solar cells," said Yeonwoong (Eric) Jung, a postdoctoral researcher in Reed's lab and also a lead author of the papers.

Journal information: Energy and Environmental Science , Nano Letters

Provided by Yale University