Using amorphous and monocristalline silicon together, researchers set new efficiency record for photovoltaic cells

(Phys.org)—This week, EPFL's Institute of Microengineering presented in Frankfurt "hybrid" photovoltaic cells with an energy conversion efficiency of 21.4 percent, the highest obtained for the type of substrate they used. This breakthrough will contribute to lower the cost of solar cell based installations.

In the medium term, an investment of only $2500 in photovoltaic cells would suffice to provide more than enough electricity for the consumption of a four people household. This promising scenario has been made possible by the innovations accomplished by EPFL's Institute of Microengineering in Neuchatel. The team of prof. Christophe Ballif, director of the Photovoltaics Laboratory (PVlab), presented their work at the European Photovoltaic Solar Energy Conference and Exhibition that just took place in Frankfurt.

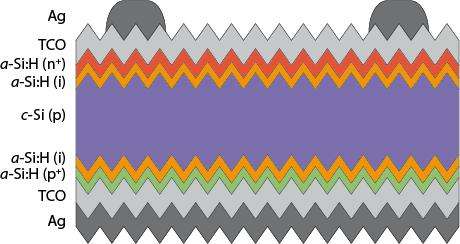

The PVlab specializes in thin film solar cells and has been interested for several years in "hybrid" technologies, better known as heterojunction technologies, designed to enhance solar captors' performance. "We apply an infinitesimal layer – one hundredth of a micron – of amorphous silicon on both sides of a crystalline silicon wafer," explains Christophe Ballif. This "sandwich" conception contributes to increase the sensors' effectiveness.

For this assembly to be efficient, the interface between the two types of silicon requires to be optimized. Antoine Descoeudres managed to achieve this feat together with Stephaan DeWolf and their colleagues. They chose the commonest – and therefore cheapest – crystalline cell (called "p-doped silicon"), took care of its preparation and improved the process of application of amorphous silicon. They obtained a 21.4% conversion efficiency, which had never been achieved before with such type of substrates: nowadays, the best quality monocrystalline cells only attain an energy conversion efficiency of 18-19% at best. In addition, the measured open-circuit voltage was 726 mV, which constitutes a first-time accomplishment as well. Last but not least, they broke the 22% efficiency barrier on a less common substrate.

These results, validated by the Fraunhofer Institute for Solar Energy Systems (ISE) in Germany, will soon be published by the IEEE Journal of Photovoltaics.

To bring these innovations to a stage of industrialization may only take a few years. This research was partly financed as a commission for Roth & Rau Switzerland, whose parent company, Meyer Burger, has already started the commercialization of machines built for assembling this type of heterojunction sensors. "Within three to five years, we expect to reach a production cost of $100 per square meter of sensors, estimates Stefaan DeWolf. In Switzerland, with the conversion efficiency achieved, such a surface will be able to produce between 200 and 300 kWh of electricity per year. "

Provided by Ecole Polytechnique Federale de Lausanne