Fused polymer-based multi-component fibers provide well-defined domains for cell co-culture in tissue engineering

(Phys.org) -- Polymer fibers play a central role in the production of biomaterials for tissue engineering applications. Generated from self-assembling polyelectrolytes, these materials provide matrices for cells to grow and differentiate. Unfortunately, polymer fibers cannot encapsulate different cell types in a spatially defined manner for culture, thereby hindering their implementation in native tissue mimics.

To overcome these limitations, Andrew Wan and Jackie Y. Ying at the A*STAR Institute of Bioengineering and Nanotechnology and co-workers have developed a method that fuses several fibers from multiple polyelectrolyte interfaces. This method creates matrices composed of well-defined, spatially patterned domains at the micrometer scale, facilitating cell co-culture within the same fiber.

Ying explains that polyelectrolyte-based fibers have previously yielded three-dimensional scaffolds for cells, inspiring the team to fuse these materials to achieve co-culture.

The team’s goal is to exploit the patterning ability of their method to give structures that emulate native tissues such as the liver. “Many cell types are involved in the liver, and they are spatially patterned with respect to each other to achieve liver function,” adds Wan.

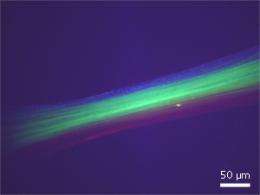

Unlike typical techniques deployed to manufacture multi-component fibers, the interfacial polyelectrolyte complexation adopted by Wan and Ying’s team is a gentle, water-based chemical process. “When two oppositely charged polyelectrolytes come into contact with each other, a complex forms at their interface,” explains Wan. “Upward drawing of this complex leads to the formation of a fiber.”

The researchers flanked a droplet of polyelectrolyte solution with two droplets of the oppositely charged polyelectrolyte, creating two interfaces from which two fibers were drawn and fused. Upon contact, the wet fibers zipped together, forming a Y-shape pattern over the droplets and producing a two-component fiber. By increasing the number of interfaces to three and four, the team obtained three- and four-component fibers.

Assessments of the ability of the fibers to enable co-culture in distinct domains showed that bone-forming cells encased in the outer layers of four-component fibers exclusively propagated and accumulated in those layers. Further experiments were carried out on fibers that consisted of a central core containing endothelial cells surrounded by outer layers filled with liver cells. The liver cells closely aggregated along the fiber without spreading to the core, where the endothelial cells had formed blood vessel-like structures.

The researchers are currently investigating ways to design better mimics of native tissue using their process. They are also planning on using the multi-component fibers to study the influence of cellular microenvironment on cancer cell behavior.

More information: Wan, A. C. A., Leong, M. F., Toh, J. K. C., Zheng, Y. & Ying, J. Y. Multicomponent fibers by multi-interfacial polyelectrolyte complexation. Advanced Healthcare Materials 1, 101–105 (2012). dx.doi.org/10.1002/adhm.201100020