This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

New strategies proposed for protecting thermal barrier coatings against environmental sediment corrosion

Lei Guo and others from Tianjin University in China discovered that the environmental sediments on the surface of aero engine turbine blades have a significant concentration of Fe, surpassing even the levels of Mg, Al, and Ca in certain zones. Consequently, they propose a CMAS-Fe composition system, including four components based on the average sediment composition observed in respective zones.

Until now, the investigation has primarily focused on the role of SiO2, CaO, MgO, and Al2O3 in the formation of the CMAS glass skeleton, while the role of Fe2O3 is often ignored. Additionally, the corrosion behavior of Gd2Zr2O7 coatings under Fe-containing environmental sediment attack is unclear.

In a study appearing in the Journal of Advanced Ceramics, they investigate the impact of Fe on the CMAS-Fe silicate glass skeleton, and explore the microstructural evolution and corrosion degradation behavior of Gd2Zr2O7 coatings under Fe-rich environmental sediments.

The presence of Fe can influence the melting point and viscosity of the melt by altering the structure of the CMAS silicate glass skeleton.

"CMAS-Fe still maintains [SiO4] tetrahedra as its fundamental glass skeleton structure. Fe acts as a network intermediate in CMAS-Fe glass, which could form tetrahedrons [FeO4] that participate in the formation of a glass skeleton, thereby increasing the melting point of CMAS-Fe," said Lei Guo, senior author of the paper, associate professor in the School of Materials Science and Engineering at Tianjin University.

"However, at high temperatures, the transformation of [FeO4] tetrahedrons into octahedral structures [FeO6] disrupts the polymerization of glass. Hence, the higher the Fe content, the lower the high-temperature viscosity of CMAS-Fe." Dr. Guo is a senior expert on the field of thermal barrier coating.

Gd2Zr2O7 coating has exceptionally low thermal conductivity, a suitable coefficient of thermal expansion, and a thermally stable high-temperature phase structure. It exhibits exceptional promise as a new TBC material, capable of withstanding temperatures exceeding 1,400 °C.

The study produced intriguing findings when the coating was subjected to various components of CMAS-Fe.

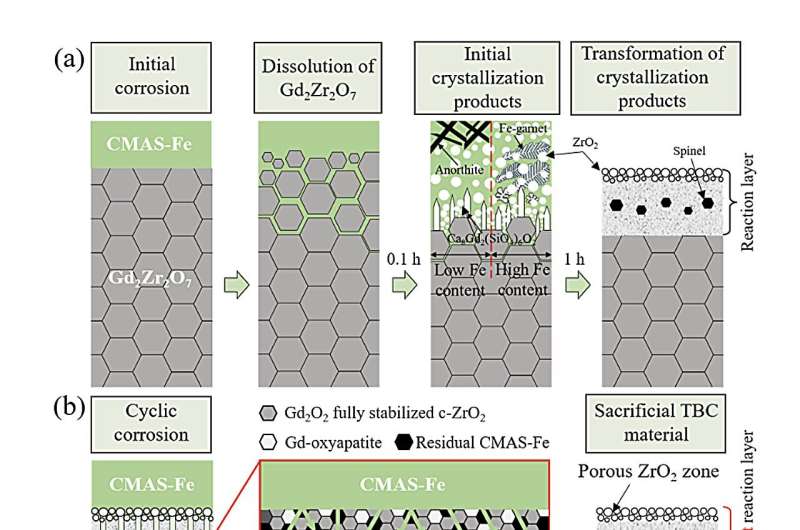

"The precipitation of crystallization products influences the corrosion resistance of the Gd2Zr2O7 coating to CMAS-Fe, which varies with Fe contents and corrosion time. During the initial corrosion, a high Ca:Si ratio facilitates the precipitation of anorthite, thereby increasing the melt viscosity," said Lei Guo.

"While a high Fe content promotes Fe-garnet precipitation. Prolonged corrosion time results in an interpenetrating network composed of Gd-oxyapatite, ZrO2, and residual CMAS-Fe. The attack of CMAS-Fe with higher Fe content results in severer degradation of crystallization products."

Under the CMAS-Fe cyclic corrosion condition, the performance of Gd2Zr2O7 coatings is unsatisfactory.

"The residual CMAS-Fe in the interpenetrating network provides a pathway for the redeposited CMAS-Fe infiltration. The precipitation of crystallization products significantly influences the melt viscosity and infiltration rate by affecting the melt composition," said Lei Guo.

Gd2Zr2O7 coatings alleviate the detrimental effects of melt through its self-consumption, resulting in continuous growth of the reaction layer and degradation in the coating performance.

In the context of developing strategies for new TBC material against environmental sediment corrosion, it is imperative to comprehensively consider the impact of diverse components. Therefore, more delicate research work is still needed to explore the mechanistic influence of specific environmental sediment components on the corrosion resistance of TBCs, which is conducive to the development of TBCs modification strategies tailored to specific local conditions.

Based on this premise, Guo also put forward some promising development directions regarding the modification of coatings including composition modification by adding rare earth elements, top layer laser glazing treatment, and designing a composite coating structure.

Other contributors include Yanyan Li from the School of Materials Science and Engineering at Tianjin University in Tianjin, China; and Kai Yan from Key Laboratory of Special Equipment Safety and Energy-saving for State Market Regulation, China Special Equipment Inspection & Research Institute in Beijing, China.

More information: Lei Guo et al, Corrosion behavior of Gd 2Zr 2O 7 thermal barrier coatings under Fe-containing environmental sediment attack, Journal of Advanced Ceramics (2024). DOI: 10.26599/JAC.2024.9220867

Provided by Tsinghua University Press