This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Customized production of antiviral coatings and cell culture surfaces

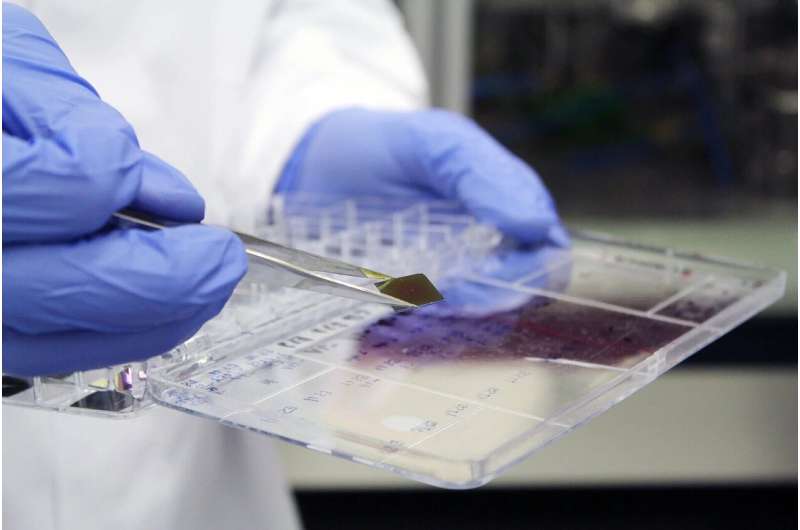

Special polymer coatings can confer functional properties to surfaces, for example, antiviral behavior. A team from the Department of Materials Science at Kiel University has now for the first time comprehensively compared various biomedical coatings and investigated what happens when they interact with the skin, with cells or with viruses.

The results have been published in the journal Advanced Materials Interfaces and applied in a first industrial project with antiviral glass.

In collaboration with the University Medical Center Schleswig-Holstein in Kiel (UKSH), the Nanotechnology Research Center Egypt and the National Cancer Institute of Cairo University, researchers of Kiel University have comprehensively compared six coating materials for biomedical applications. The team investigated the bio-interface-performance of the material surfaces to respiratory viruses, cancer cells and fibroblasts.

"For example, we looked at where key proteins, such as the spike protein of the coronavirus, dock onto material surfaces and show antiviral behavior," says materials scientist Torge Hartig, first author of the study. For antiviral coatings against coronaviruses, the team was able to show that such interactions can also be calculated to narrow down the number of potential materials.

Production method enables comparison

This detailed investigation is only possible because of the method the team of Kiel produces the coatings. For many years, they have been working on the initiated chemical vapor deposition (iCVD) at Professor Franz Faupel's Chair for Multicomponent Materials.

"This enables us to produce transparent coatings and adjust their thickness with high precision between 10 nanometers and 10 micrometers. Their surface is ultra-smooth, extremely uniform and has no disturbing defects," says Hartig.

This is crucial because many factors typically play a role in contact with coatings. With conventional polymer coatings, for example, the surface topography, chemical processes, solvent residues or material defects can influence interactions with viruses or cells.

"With our technology, we produce coatings that are so pure that all other factors apart from chemical processes can be excluded and we can fundamentally analyze the actual interactions between the coating and viruses or cells," continues Hartig, who is doing his doctorate thesis on biomedical iCVD coatings.

From ambulances to supermarket checkouts: Coatings tested with window manufacturers

The materials scientists can control their production process very well and thus predict and define the functional properties of their coatings in a targeted manner—for example, to fulfill the high requirements in biomedical environments.

"We can coat products for cell culture in such a way that the cells adhere better and are easier to cultivate," says Dr. Stefan Schröder, leader of the iCVD activities at the Chair. As their method requires no solvents and only few chemicals, it is also significantly more environmentally friendly than conventional wet-chemical coating processes.

Together with a window manufacturer from Southern Germany, the materials scientists from Kiel have put their findings into practice. "We compared several antiviral coatings and applied the best one to window glass," says Schröder.

Large glass facades cannot yet be coated, "but small surfaces that are exposed to a lot of contact, such as touch displays in hospitals and ambulances, filters in breathing masks or cash registers at supermarket checkouts," says Schröder, who also wrote his doctoral thesis on the iCVD process.

A team from the chair now wants to apply the iCVD research of recent years on an industrial scale and is currently preparing a spin-off. "Our goal is to produce particularly high-quality coatings with customized properties for medicine and industry," says Hartig, who joined the start-up initiative "conformally" while still working on his doctorate. In addition to antiviral properties, these coatings can also be water-repellent or insulating, for example—or even a combination of both.

More information: Torge Hartig et al, iCVD Polymer Thin Film Bio‐Interface‐Performance for Fibroblasts, Cancer‐Cells, and Viruses Connected to Their Functional Groups and In Silico Studies (Adv. Mater. Interfaces 1/2024), Advanced Materials Interfaces (2024). DOI: 10.1002/admi.202470002

Provided by Kiel University