This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Combining electron microscopy and simulations to get a thorough understanding of an iron and aluminum alloy

The compound of iron and aluminum with the chemical formula Fe3Al has some very useful mechanical properties. A team from Osaka University has combined simulations with experimental techniques to better understand the kinetics of the formation of microstructures to enhance and utilize these properties for specific applications.

In a study published in Acta Materialia, the researchers took an in-depth look at the way the microstructure of Fe3Al develops because the ordered domains that form contribute to one of its key properties: superelasticity.

When high loads are applied to superelastic materials they can deform to large strains which would result in a permanent strain in conventional materials without break. Interestingly, they can return to their original shape when unloaded. This can be used in a diverse range of applications from health care materials to seismic devices for construction materials.

Superelasticity results from the way the atoms are arranged in a material. This can differ between materials. In the most well-known superelastic material, i.e. TiNi alloys,which consist of precious and rare metals of titanium and nickel, the change of crystal structures in response to the load (i.e. Martensitic transformation) is responsible for the large plastic deformation and the recovery of the shape.

In contrast, in Fe3Al consisting of common metals of iron and aluminum, the superelastic properties are caused not by the change of crystal structure but by dislocation slip, which is the relative displacement of atoms keeping crystal structure. Dislocation slip normally gives rise to permanent strain, except when there is a force that can give rise to the back motion of dislocation.

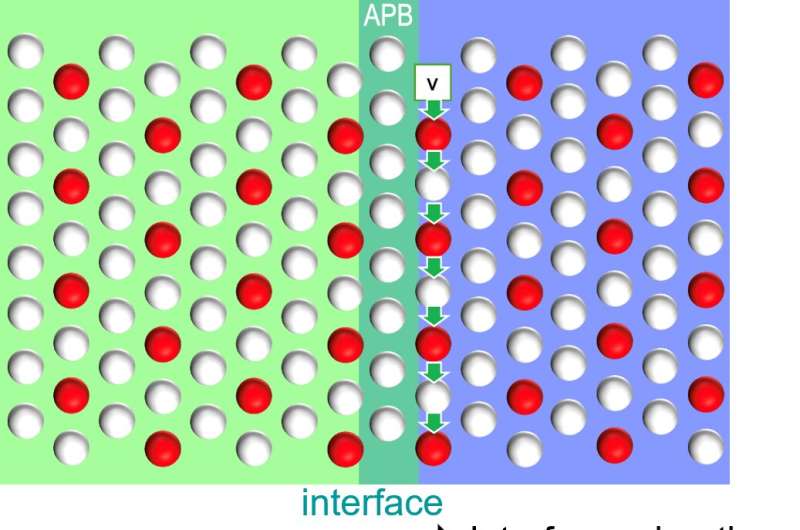

In Fe3Al, the back motion of dislocation can be caused by antiphase boundaries (APB) which separates areas within a material known as domains, and the shape and size of the boundaries between these domains contribute to the superelastic properties.

"To harness particular material properties and ensure they are appropriate for their application, you have to understand what is happening," explains study lead author Yuheng Liu.

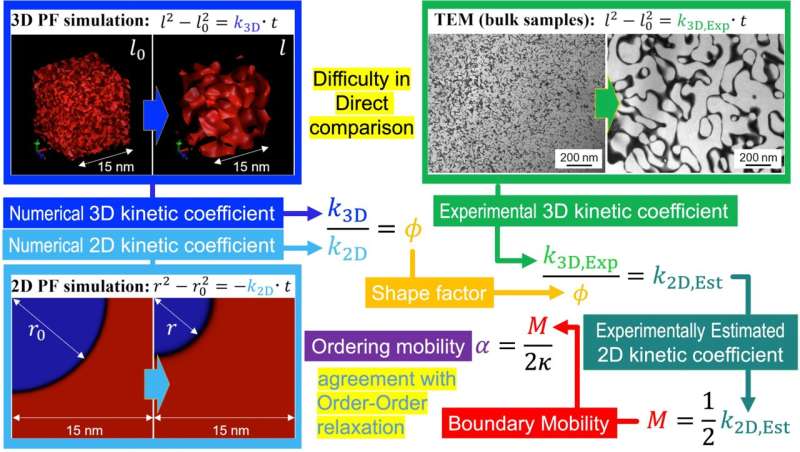

"Until now, ordering mobility studies of the atoms in Fe3Al have led to different interpretations depending on the experimental technique. We have therefore combined phase-field computer simulations and transmission electron microscopy (TEM) experiments to finally get a good picture."

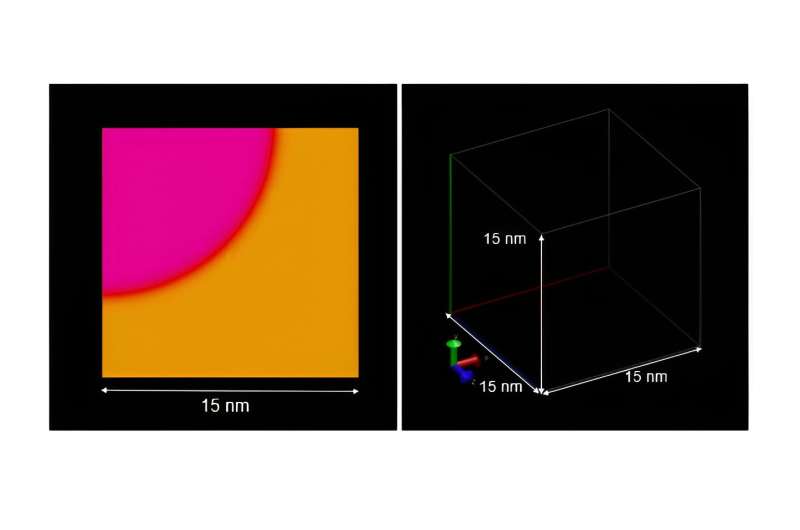

The computer simulations predicted the 3D shapes of the areas in the Fe3Al with ordered structure. These findings were then compared with TEM observations for Fe3Al samples heated to different temperatures. The combined data revealed the mobility for forming the ordered D03-type structure.

The D03 structure of Fe3Al is similar to L21 structure of other materials. The findings could therefore provide a starting point for exploring heat treatments for other functional materials, including half metals for spintronics, which may become crucial for quantum computing in the near future.

"It is challenging to design experiments that can capture the movement of boundaries and the details of how the microstructure evolves, particularly in the early stages of ordering," says senior author Yuichiro Koizumi. "The phase-field simulations provide a window into the process that has been missing from previous studies."

The study findings are expected to support applications in the construction industry. For example, Fe3Al could be used to 3D print structural parts that can act as shock absorbers for seismic activity.

More information: Yuheng Liu et al, Resolving the long-standing discrepancy in Fe3Al ordering mobilities: A synergistic experimental and phase-field study, Acta Materialia (2024). DOI: 10.1016/j.actamat.2024.119958

Journal information: Acta Materialia

Provided by Osaka University