This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Research progress of layered double hydroxide-based electrocatalyst for water splitting

In the context of the gradual depletion of fossil fuels and the energy crisis, hydrogen energy has attracted widespread attention due to its ultra-high energy density and eco-friendly properties. However, most of the hydrogen production still relies on fossil fuels, with less than 1 million tons produced as low-emission hydrogen in 2021, which means it has limited benefits in mitigating the energy crisis and environmental degradation.

Alternatively, hydrogen production via water electrolysis has the advantages of non-polluting products, sustainable regeneration, and abundant reactant storage, making it an attractive option for further development.

Since driving the water electrolysis requires overcoming a significant overpotential, it is essential to use efficient catalysts that can reduce the overpotential. Layered double hydroxide (LDH)-based materials are considered promising electrocatalysts for water splitting due to the advantages of unique layered structure, flexible tunability, high specific surface area and distinct electron distribution.

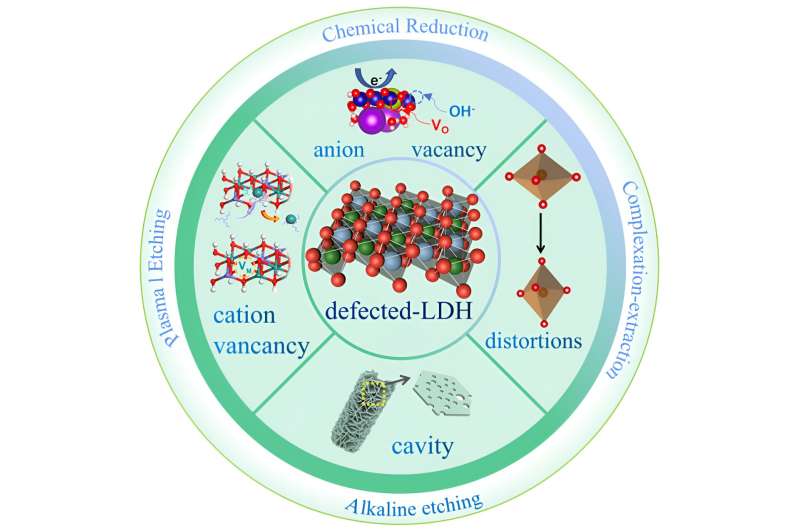

However, the low conductivity and limited active sites hinder the industrial applications of LDH-based electrocatalysts. Defect engineering is an effective strategy to tune the local surface microstructure and electronic structure, which can efficiently address the drawbacks of LDH.

Recently, Prof. Deli Wang's team from Huazhong University of Science and Technology, China, reported the recent defect fabrication strategies on LDH and systematically discussed how defects affect the electrocatalytic behavior of LDH. The review was published in Chinese Journal of Catalysis

To begin with, the fundamental mechanism of water electrolysis and the challenges faced by LDH as an electrocatalyst for water electrolysis are presented. And then, the superiority of defect engineering for improving the electrocatalytic performance of LDH is presented and a series of defect fabrication strategies on LDH are summarized and discussed in detail.

Subsequently, the relationship among catalytic activity, stability, morphology, structure, composition and defect types are analyzed and discussed. Finally, the challenges and prospects of applying defect engineering on LDH are discussed.

More information: Junhao Yang et al, Defects engineering of layered double hydroxide-based electrocatalyst for water splitting, Chinese Journal of Catalysis (2023). DOI: 10.1016/S1872-2067(23)64557-7

Provided by Chinese Academy of Sciences