This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

New rapid prototyping method for microscale spiral devices

A team of researchers from Tohoku University and Okinawa Institute of Science and Technology (OIST) has achieved significant advancement in the field of microfluidics, allowing for precise and efficient manipulation of fluids in three-dimensional microscale environments. This work opens up new possibilities for bioanalytical applications, such as cell separations in the realm of medical diagnostics.

Details of their breakthrough were published in the journal Microsystems & Nanoengineering on January 22, 2024.

Microfluidic devices are designed to handle minuscule fluid volumes, allowing researchers to perform analyses and processes with remarkable precision and efficiency.

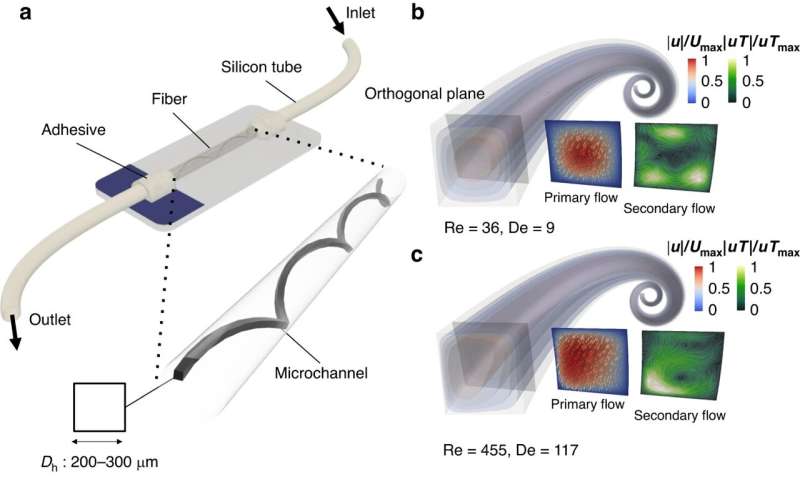

In recent years, microfluidic technology has rapidly advanced across various fields, including medicine, biology, and chemistry. Among them, three-dimensional spiral microfluidic devices stand out as game-changers. Their intricate corkscrew-like design allows for precise fluid control, efficient particle separation, and reagent mixing. However, their potential to revolutionize bioanalytical applications is hindered by the current challenges in fabrication. The process is time-consuming and costly, and existing manufacturing techniques limit material options and structural configurations.

To overcome these limitations, an interdisciplinary team from Tohoku University and OIST has introduced a miniaturized rotational thermal drawing process (mini-rTDP), drawing inspiration from traditional Japanese candy-making techniques—the fabrication of Kintaro-ame.

Their innovative approach involves rotating the materials during thermal stretching to create intricate three-dimensional structures within fibers. This process is highly versatile, accommodating a wide range of materials that can deform when heated, unlocking endless possibilities for combining diverse materials.

"Mini-rTDP facilitates rapid-prototyping of three-dimensional microfluidic systems, ideal for precise biofluid manipulation," says Yuanyuan Guo, an associate professor at Tohoku University's Frontier Research Institute for Interdisciplinary Sciences (FRIS).

"Mini-rTDP involves creating a molded polymer preform containing channels, which are subsequently stretched and heated to generate microfluidic channels within a fiber. These channels can then be further rotated to shape three-dimensional spiral configurations", explains Shunsuke Kato, a junior researcher at FRIS and the first author of the paper.

In collaboration with Amy Shen, leader of the Micro/Bio/Nanofluidics Unit at OIST, the interdisciplinary Tohoku-OIST team conducted both simulations and experiments to visualize fluid flows within the spiral structures. Daniel Carlson from Shen's team says, "We have confirmed the presence of Dean vortices, a type of rotational flow occurring in curved channels, in our devices, thus affirming their potential for significantly enhancing cell and particle separation efficiency."

"The rapid prototyping of three-dimensional spiral microfluidics using mini-rTDP represents a remarkable advancement in the field of microfluidics. This technology offers unparalleled versatility, precision, and the potential to catalyze transformative changes across various industries," says Shen.

"Furthermore, we are actively pursuing the integration of microfluidic channels with functionalities such as electrodes, biosensors, and actuators directly into fibers. This endeavor has the potential to revolutionize Lab-on-Chip bioanalytical technologies," said Guo.

This research is a testament to the collaborative efforts of the OIST SHIKA program and the matching funds provided by Tohoku University, highlighting the strong partnership and synergy between these two institutions.

More information: Shunsuke Kato et al, Twisted fiber microfluidics: a cutting-edge approach to 3D spiral devices, Microsystems & Nanoengineering (2024). DOI: 10.1038/s41378-023-00642-9

Journal information: Microsystems and Nanoengineering

Provided by Tohoku University