This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers turn potato chip bags into energy-saving cooling films

Films made of aluminum-plastic laminates (APL) have long been used extensively to extend the shelf life of chips, roasted and powdered coffee, milk, fruit juices and other foods. During the COVID-19 pandemic, they were used to package FFP2 masks and rapid tests.

The films consist of several polymer layers and an aluminum layer, which protects the products from damaging factors—especially from sunlight and heat, but also from moisture and oxygen. However, recycling such composite films is difficult as a result of this combination of different materials.

The upcycling process of chips bags now developed in Bayreuth shows a way to improve the recycling of APL waste and, at the same time, reduce global energy consumption. Cooling systems already account for around 15 % of global energy consumption, and in view of climate change and the occurrence of heat waves, this share threatens to continue to rise.

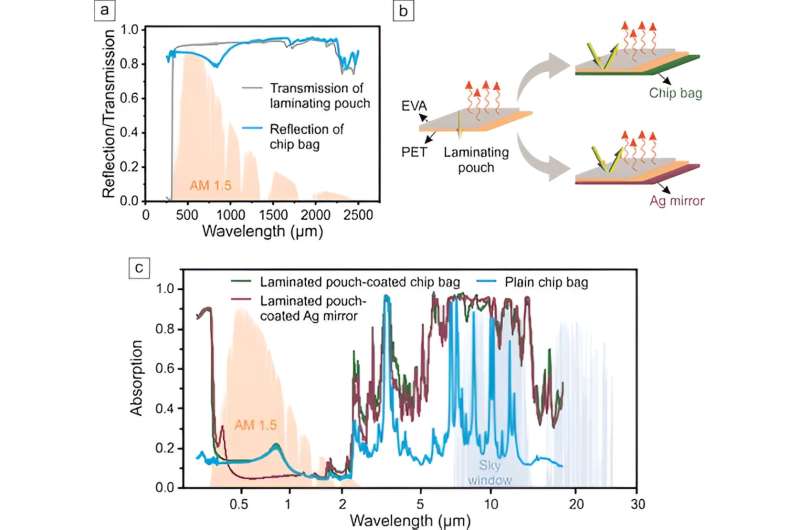

The aluminum layer of APL packaging provides a mirror-like reflective surface, such as that found on emergency blankets. If a clear polymer layer is now applied that increases the radiation of thermal energy, a powerful cooling system is complete. A simple laminating film, such as is commonly found in office supply stores, is already sufficient as a material for the coating.

The coating creates cooling foils that can be applied to any surface in the open air—such as umbrellas, blinds and awnings—and thus prevent heating from glaring sunlight. At the same time, the ambient heat is diverted to the cool space without the need for an external energy supply. These effects are referred to as "passive daytime cooling". Ideally, they can lead to temperatures below the ambient temperature, even in the case of intense sunlight.

Passive daytime cooling is made possible by the fact that the materials used meet special optical requirements. They must scatter or reflect as much of the sunlight as possible, which has a wavelength between 0.3 and 2.5 micrometers. On the other hand, in the wavelength range between 8 and 13 micrometers, the so-called sky window, they must emit as much thermal energy as possible into space in the form of infrared radiation.

Aluminum-plastic composite foils fulfill these requirements very well. Using the example of coated commercial potato chips bags, the Bayreuth researchers have demonstrated: Around 87 % of the sunlight is reflected by the aluminum layer. The additional polymer coating of the new sustainable cooling foils improves the radiation in the wavelength range of the sky window and thus emits heat directly into space.

Prof. Dr. Markus Retsch and his colleague Dr. Qimeng Song have tested different ways of turning potato chip bags and other APL packaging into efficient cooling materials. Industrial processes that use polydimethylsiloxane (PDMS) as a coating material are possible. But as the recent study published in ACS Sustainable Chemistry & Engineering shows, it is also conceivable that the coating process could be undertaken by anybody in the future.

Simple commercial laminating equipment is all that is needed to turn old APL packaging into cooling materials that can be used as heat shields on patios, balconies, exterior walls or roofs.

Additional research is published in Advanced Materials Technologies.

More information: Qimeng Song et al, Passive Daytime Cooling Foils for Everyone: A Scalable Lamination Process Based on Upcycling Aluminum-Coated Chips Bags, ACS Sustainable Chemistry & Engineering (2023). DOI: 10.1021/acssuschemeng.3c00683

Qimeng Song et al, Upcycling Chips‐Bags for Passive Daytime Cooling, Advanced Materials Technologies (2023). DOI: 10.1002/admt.202300444

Journal information: ACS Sustainable Chemistry & Engineering , Advanced Materials Technologies

Provided by Bayreuth University