This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Fixing hidden damage in carbon-fiber reinforced epoxy materials with a resin-injection method

A team of researchers from Singapore and the UK, led by Dr. Wei Liang Lai, with supervisor, Associate Professor Kheng Lim Goh, has developed a portable device for repairing hard-to-see damage in carbon fiber materials. The device has great potential for the aerospace industry, such as to repair the fuselage of commercial aircraft. Their work has been published in the journal Polymers for Advanced Technologies.

A new handheld device has been created to fix almost invisible damage on materials made from carbon fiber and epoxy. The researchers tested this device on materials with different numbers of layers, 16 and 24, and tried three types of adhesives: regular epoxy, epoxy mixed with special particles called halloysite nanotubes (E1HNT), and epoxy mixed with carbon nanotubes (NF100, also known as "NanoForce E100" from Nano-Tech SPA. They used infrared technology and compression testing to see how well the repairs worked.

Unfortunately, all the damaged materials were much weaker than undamaged ones. The researchers found that the number of layers in the material was the most important factor affecting how well the repair worked. For the 16-layer material, using regular epoxy or E1HNT in a vacuum worked best for restoring its stretchy properties, while using E1HNT adhesive at regular atmospheric pressure worked best for fixing its fractures.

However, for the 24-layer material, the repairs didn't fully bring back its original strength because the damage was more complicated. The researchers discussed which repair methods were most effective for restoring certain properties of the materials.

Prior to this study, the researchers had studied the properties of different types of resin to find out which ones would work best for repairing damaged composite materials. They considered the halloysite nanotubes (HNT) and carbon nanotubes (CNT) that can be mixed into adhesives to make them better for fixing the damaged materials. However, they needed to check how well these particle-adhesive blends performed, considering factors like how they were prepared, the effects of the types of particles used, and how much of them were added.

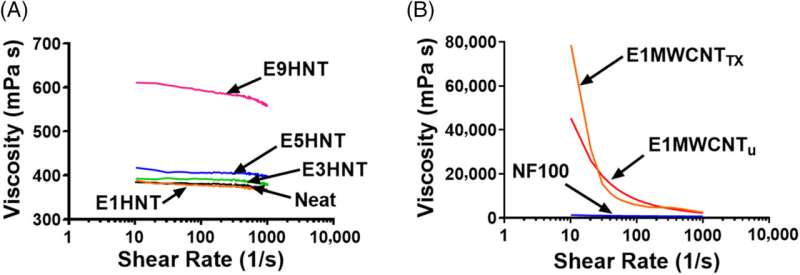

They studied two commercially available adhesives, Epo-Tek 301 and NanoForce E100, and also prepared mixtures of Epo-Tek 301 with different amounts of HNTs, and Epo-Tek 301 with treated and untreated CNTs.

They examined various properties of these adhesives, including how strong they were (using a dedicated micromechanical tester developed jointly by researchers from Sensorcraft Technology (S) Pte Ltd and Newcastle University in Singapore), how well they stuck to things, their physical traits like how they spread out, their ability to handle heat and their chemical characteristics.

The results showed that adding 1% of HNTs to Epo-Tek 301 didn't change its properties much, but using more HNTs made the adhesive weaker and changed its behavior when exposed to heat. On the other hand, adding CNTs didn't make the adhesive any better in terms of its properties. In fact, the adhesives with CNTs became thicker and might not work well for repairing composite materials since they might not seep into the damaged areas easily.

So, when choosing an adhesive to repair damaged composite materials, it's important to choose wisely considering all these factors.

More information: W. L. Lai et al, In situ resin‐injection approach for repairing barely visible impact damaged carbon‐fiber reinforced epoxy laminates: Optimizing the repair parameters using Taguchi method, Polymer Composites (2023). DOI: 10.1002/pc.27327

Wei Liang Lai et al, Experimental assessment on the mechanical, physical, thermal, and chemical properties of halloysite and carbon nanoparticles reinforced epoxy resins for repair applications, Polymers for Advanced Technologies (2023). DOI: 10.1002/pat.6150

Provided by Newcastle University in Singapore