This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Team fabricates chitin hydrogel via chemical transformation of chitosan

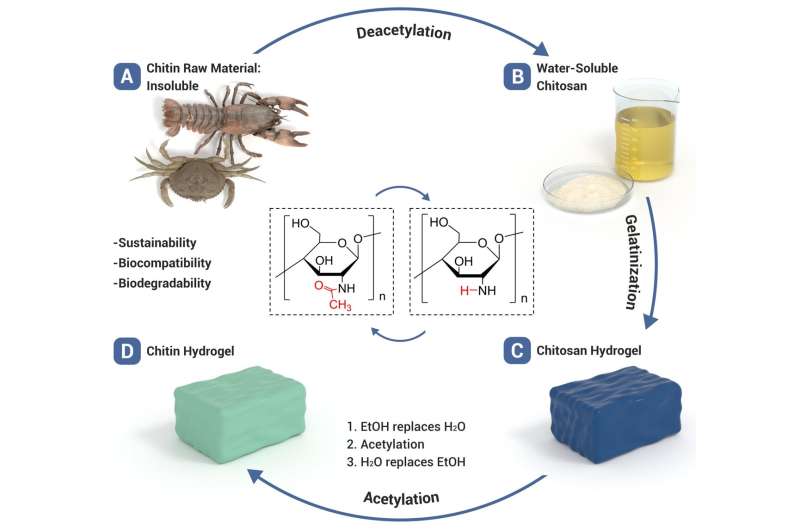

Chitin hydrogel is recognized as a promising material for a variety of biomedical applications. Its biocompatibility and biodegradability make it useful in tissue repair, artificial organs, and wound healing. Yet scientists continue to face challenges in fabricating chitin hydrogel. A team of researchers has developed a green, efficient and scalable preparation method for chitin hydrogels.

The team's work provides a rational strategy to fabricate chitin hydrogels and paves the way for its practical applications as a superior biomedical material.

Their findings are published in the journal Nano Research.

Chitin, the second most abundant natural polymer, is a substance that comes from the exoskeletons of crabs, prawns, and insects. Chitin is renewable, degradable, biocompatible and low-cost. These qualities make it an excellent candidate for various biomedical uses.

"Chitin hydrogel, which shares many similarities with extracellular matrix, is an ideal material for tissue engineering and regenerative medicine. However, it is a challenge to dissolve chitin in aqueous solutions to produce hydrogel materials. Therefore, it is of great significance to develop rational fabrication strategy," said Li-Bo Mao, a professor at the University of Science and Technology of China.

To be useful in biomedical applications, the chitin hydrogel must be biologically safe and have the appropriate mechanical strength and chemical stability. It must resist biofouling, which could lead to inflammatory response or immune rejection in the human body. For commercial use, the chitin hydrogel must also be low-cost and scalable.

The challenges in fabricating strong chitin hydrogel arise because of the insolubility of chitin in many solvents and the reduced chain length of chitin regenerated from solutions. Biopolymer hydrogels are typically prepared with a two-step process: the dissolution of the biopolymer and the subsequent gelation.

However, chitin is not soluble in water or other common solvents because of the numerous inter- and intra-molecular hydrogen bonds between the polymer chains. The team tackled this challenge by fabricating chitin hydrogel with biomimetic structure through the chemical transformation of chitosan, a water-soluble deacetylated derivative of chitin.

Chitosan is easily dissolved in water in the presence of acids. These chitosan hydrogels can be endowed with different microstructures. However, they are not mechanically or chemically stable. Attempts to improve them by using crosslinking agents have raised biosafety concerns.

The team was successful in fabricating a chemically stable and antifouling chitin hydrogel via a chemical reaction called acetylation. Through the acetylation process, the chitin hydrogel the team obtained possesses outstanding resistance to swelling, degradation, extreme temperature and pH conditions, and organic solvents.

The team also learned that by templating the chitosan precursor with ice crystals, they could produce chitin hydrogels with different biomimetic structures. These structures can be either nacre-like or wood-like depending on the freezing method used with the chitosan precursor.

The chitin hydrogel developed by the team has excellent mechanical properties while retaining a high water content. It also shows excellent antifouling performance, resisting the adhesion of proteins, bacteria, blood, and cells.

"Besides the many advantages that are characteristic to chitin, the hydrogel materials we obtained are mechanically strong and robust. In addition, the hydrogels can be feasibly processed into different shapes and structures. These ensure the practical applications of the chitin hydrogels," said Mao.

Looking ahead, the team's next step is to further improve the mechanical properties of chitin hydrogels and explore their biomedical applications via in vivo experiments. "We anticipate various chitin-based hydrogel materials can be fabricated through this strategy and used for different clinical applications, such as cartilage replacement, bone replacement, wound dressing and even artificial organs," said Mao.

More information: Rui-Rui Liu et al, Biomimetic chitin hydrogel via chemical transformation, Nano Research (2023). DOI: 10.1007/s12274-023-5886-5

Journal information: Nano Research

Provided by Tsinghua University Press