This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Superlattice films developed to achieve macroscale superlubricity

A research group led by Prof. Wang Liping at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. Li Qunyang at Tsinghua University, developed a universal superlattice film that can be applied to mechanical parts to achieve long-term macroscale superlubricity with self-rejuvenation. The study was published in Cell Reports Physical Science.

It is estimated that about one-third of global energy is consumed to get rid of friction, which is quite common in nature. Reducing friction to an ultra-low level or even a superlubricious state with a friction coefficient on the order of 10-3 can exert significant impacts on human life. However, achieving robust macroscale superlubricity between dry solid surfaces remains a challenge, which has been realized mainly at nanometer scales with lamellar materials in previous studies.

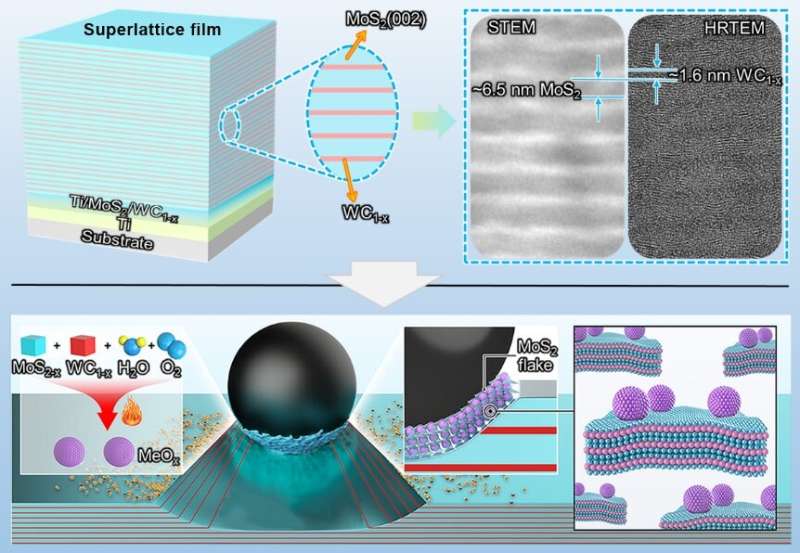

To tackle this challenge, the researchers designed a universal molybdenum disulfide (MoS2) /ceramic superlattice architecture, which enables long-term (close to 300,000 sliding cycles) macroscale superlubricity in mild vacuum after a short running-in period in air.

The precise thickness control of each individual sublayer within the bilayer unit endows the film with such excellent superlubricity (friction coefficient of 0.006). More interestingly, the lubrication capability can be rejuvenated when the film is accidentally exposed to air.

The superlubricious interface is believed to result from the sliding of MoS2-wrapped metal oxides (MeOx) nanoparticles sandwiched between highly ordered MoS2 flakes, dividing the macroscopic contact area into numerous incommensurate nanocontact zones to ensure robust superlubricity.

Benefiting from the robust superlubricity, the specific wear rate of the superlattice film was reduced to an ultralow level on the order of 10-9 mm3 N-1 m-1.

These findings offer a novel strategy for designing versatile solid lubricants, which may contribute to revolutionary applications both on the ground and in space.

More information: Siming Ren et al, Macroscale superlubricity enabled by rationally designed MoS2-based superlattice films, Cell Reports Physical Science (2023). DOI: 10.1016/j.xcrp.2023.101390

Journal information: Cell Reports Physical Science

Provided by Chinese Academy of Sciences