This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Your fork could someday be made of sugar and wood powders and degrade on-demand

Single-use hard plastics are pervasive: utensils, party decorations and food containers, to name a few examples. These items pile up in landfills, and many biodegradable versions stick around for months, requiring industrial composting systems to fully degrade. Now, researchers reporting in ACS Sustainable Chemistry & Engineering have created a sturdy, lightweight material that disintegrates on-demand—and they made it from sugar and wood-derived powders.

Sturdy, degradable materials made from plants and other non-petroleum sources have come a long way in recent years. For example, cornstarch-based packing peanuts disappear simply by dousing them in water, and some utensils are based on polymers synthesized from plant sugars.

But those packing peanuts can't be used to protect anything wet, and plant-derived polymers still take a long time to break down. One potential alternative is a new type of rigid material designed from isomalt, which is a sugar alcohol rather than a polymer. With isomalt, bakers can create breathtaking, but brittle, structures for desserts, and then dissolve them away quickly in water. So, Scott Phillips and colleagues wanted to boost the sturdiness of isomalt with natural additives to create a robust material that degrades on-demand.

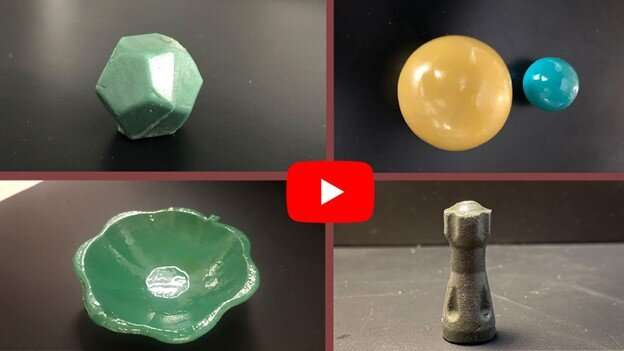

The researchers heated isomalt to a liquid-like state and mixed in either cellulose, cellulose and sawdust, or wood flour to produce three different materials. Then, using commercial plastics manufacturing equipment, the materials were extruded into small pellets and molded into various objects, including balls, a dodecahedron, a chess piece and flower-shaped saucers.

All of the tested additives doubled the strength of isomalt, creating materials that were harder than plastics, including poly(ethylene terephthalate) (known as PET) and poly(vinyl chloride) (known as PVC), but were still lightweight. In experiments, samples dissolved in water within minutes.

And saucers made of the material, and coated with a food grade shellac and cellulose acetate, withstood being immersed in water for up to seven days. However, once the saucers were broken and the coating cracked, they rapidly disintegrated in water. The team also repeatedly crushed, dissolved and recycled both coated and uncoated objects into new ones that were still as strong as the original items.

The researchers say that the material could be used for food-service items and temporary décor, and then crushed and sprayed with water to fall apart. But even if such items were simply tossed into the trash or somehow got into the environment, the slightest crack in the coating would start their collapse into sugars and the plant-based additives, which the researchers say might be good for soil.

More information: Terra Miller-Cassman et al, Amorphous Sugar Materials as Sustainable and Scalable Alternatives for Rigid, Short-Term-Use Products, ACS Sustainable Chemistry & Engineering (2023). DOI: 10.1021/acssuschemeng.2c06981

Provided by American Chemical Society