This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Want a stronger biodegradable plastic? Add a 'pinch' of cream of tartar

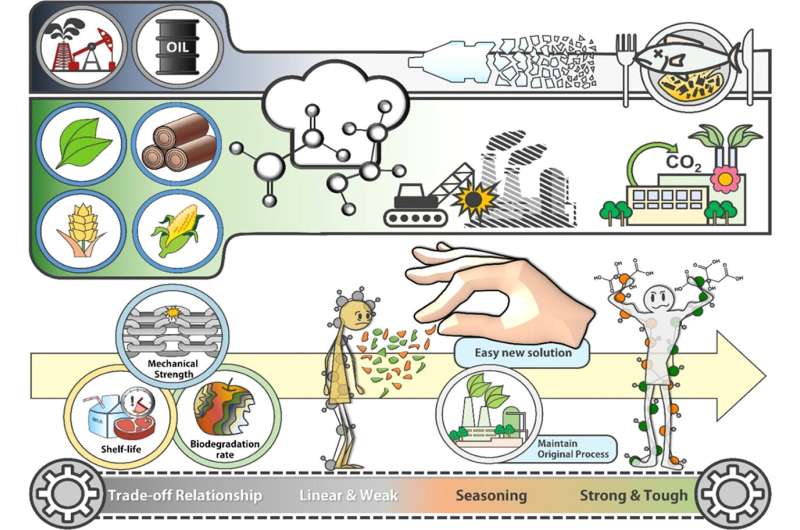

Cooking a delicious risotto and making plastics are actually very similar processes. In both, ingredients come together and are heated to create a product, but current recipes for synthesizing bioplastics often fall flat, producing flimsy materials. So, taking a hint from chefs, researchers now report in ACS Sustainable Chemistry & Engineering a way to "season" biodegradable plastics to make them stronger. It just takes a "pinch" of cream of tartar (tartaric acid) or citric acid.

To help reduce the amount of plastic waste, some companies are adopting biodegradable plastics that eventually disintegrate. However, it's often the case that the more easily these materials break down, the flimsier they are, tearing apart from the slightest pressure. One solution could be to sprinkle in additives, similar to salt and pepper seasonings in cooking, to increase strength and toughness.

Some researchers have used petroleum-based additives, but they can slow down degradation and are unappealing to consumers who desire products made from natural, biologically sourced ingredients. So, Jeyoung Park, Dongyeop Oh, Hyeonyeol Jeon, Jun Mo Koo and colleagues wanted to see if "seasoning" a biodegradable bioplastic called poly(butylene succinate) (PBS) with fruit-derived tartaric acid or citric acid could improve the plastic's mechanical properties.

The researchers made seasoned PBS by first heating succinic acid and 1,4-butanediol with small amounts of either tartaric or citric acid. Then, they added titanium(IV) butoxide and dried the products. In tests, the two new films stretched more than twice as far before breaking and let through less oxygen compared to pure PBS. These results indicate that, unlike the original version, the new materials could be successfully used for bags or food packaging, say the researchers.

Additionally, the two seasoned materials were stronger than many conventional biodegradable plastics and some petroleum-based products. One potential downside is that it took the new additive-containing polymers slightly longer to break down in water compared to pure PBS over 14 weeks, though that could be beneficial for food packaging applications in humid environments.

Because the "seasoning" approach is relatively simple, the researchers say the new plastics could be made using current industrial processes, potentially replacing petroleum-based polymers.

More information: Hyeri Kim et al, Toward Sustaining Bioplastics: Add a Pinch of Seasoning, ACS Sustainable Chemistry & Engineering (2023). DOI: 10.1021/acssuschemeng.2c06247

Provided by American Chemical Society