This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Next-generation aramid fiber with electrical conductivity

Aramid fiber is known as "super fiber," or "golden silk," because even though its weight is equivalent to only 20% of the weight of steel, it is more than five times as strong and does not burn, even at 500°C. Aramid fiber is an essential material used in various applications such as body armor, fire-resistant clothing, fiber optic cable reinforcement, high-performance tires, and aerospace materials. The late Dr. Han-Sik Yun began researching aramid fiber at the Korea Institute of Science and Technology (KIST) in 1979 and secured independent source technology in 1984.

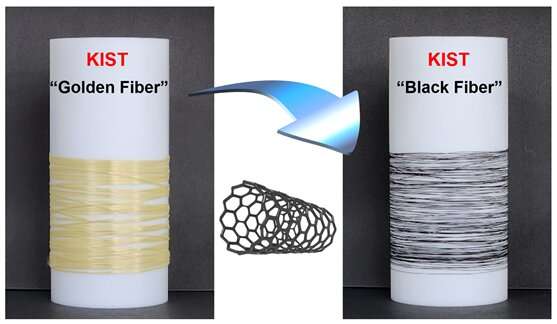

Dr. Dae-Yoon Kim and his research team at the Functional Composite Materials Research Center within the KIST Jeonbuk Institute of Advanced Composite Materials announced that they have applied carbon nanotubes to aramid fibers to develop a new kind of composite fiber. The findings are published in the journal Advanced Fiber Materials.

In addition to being lightweight, strong, and fire-resistant, the fiber also has electrical conductivity, which is a first for conventional aramid fibers. The newly developed fiber is black in color due to the presence of carbon nanotubes.

Inspired by the characteristics of a silkworm cocoon, the KIST research team succeeded in combining aramid, which has extremely low dispersibility, with carbon nanotubes. By utilizing the liquid crystal phase, silkworms produce high-strength fiber using high-concentration protein. Possessing both liquid-like fluidity and crystal-like order, the liquid crystal minimizes the coagulation of aramid and carbon nanotubes as well as improves the alignment.

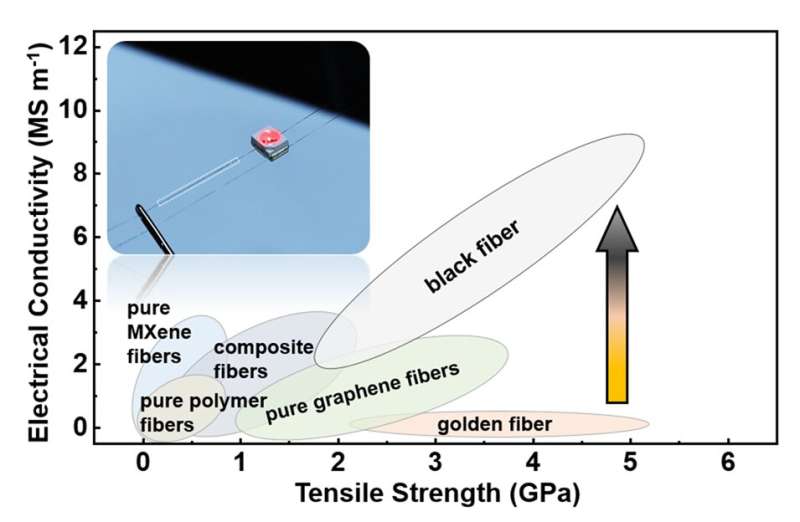

Utilizing these characteristics, the research team created a new type of composite fiber with high level of specific strength similar to that of existing commercial aramid fibers, as well as a specific electrical conductivity level of approximately 90% of that of copper wires.

Despite these electrical characteristics, this next-generation aramid fiber does not use any metals, resulting in flexibility, non-corrosiveness, and a lightweight profile (approximately 30% of the weight of copper wires). It is expected to be used as a next-generation wire in various applications, such as smart military, medical robots, eco-friendly mobility, and aerospace technologies. Dr. Dae-Yoon Kim added, "This technology will have a significant impact on the super fiber market."

More information: Ki-Hyun Ryu et al, Boost Up the Mechanical and Electrical Property of CNT Fibers by Governing Lyotropic Liquid Crystalline Mesophases with Aramid Polymers for Robust Lightweight Wiring Applications, Advanced Fiber Materials (2022). DOI: 10.1007/s42765-022-00246-4

Provided by National Research Council of Science & Technology