This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Development of cost-effective and strong composite carbon fiber using carbon nanotubes

Carbon nanotubes are a novel material that is 100 times stronger than steel while only one-fourth its weight and has electrical conductivity as high as that of copper. If fibers could be made using carbon nanotubes, theoretically, these fibers could surpass the performance of existing carbon fibers, making carbon-nanotube-based fibers a novel material of interest in the aerospace, military, and mobility industries. However, maintaining the superior properties of carbon nanotubes in fibers is very challenging, and the commercialization of such fibers is difficult due to the extremely high cost of carbon nanotubes.

A research team led by Dr. Bon-Cheol Ku of the Korea Institute of Science and Technology (KIST) Jeonbuk Institute of Advanced Composite Materials collaborated with a research team led by Professor Han Gi Chae from the Ulsan National Institute of Science and Technology (UNIST) to develop a low-cost fabrication technology for carbon-nanotube-based composite carbon fibers with extremely high tensile strength and high modulus. The study is published in the journal Composites Part B: Engineering.

Generally, carbon fibers are manufactured as high-strength fibers based on the polymer polyacrylonitrile (PAN) or highly modulus fibers using pitch derived from pyrolyzed fuel oil. The research team developed a technology that greatly improved the modulus while maintaining high strength by utilizing carbon nanotubes and polyimide (PI).

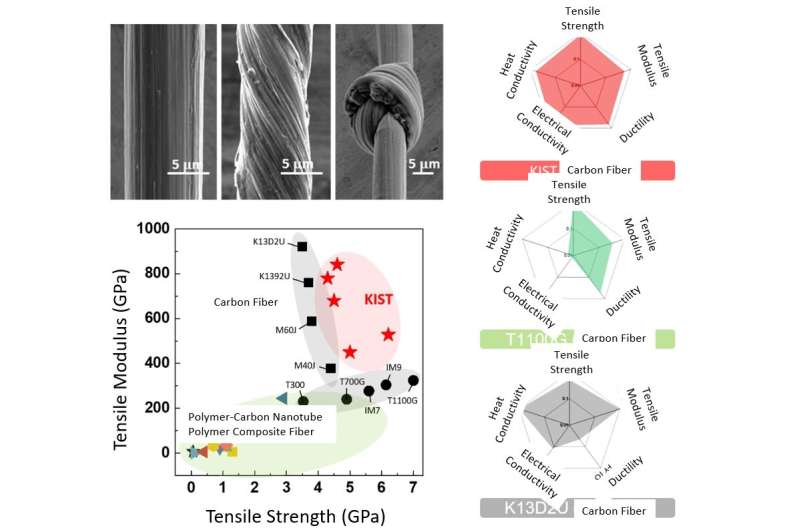

The team successfully fabricated fibers with high modulus (528 GPa) and high strength (6.2 GPa) by initially creating a carbon nanotube and polyimide composite fiber using a continuous wet spinning process and then applying a high-temperature heat treatment. The reported modulus is 1.6 times greater than that of commercially available fibers (~320 GPa).

Additionally, microstructure analysis verified that the physical properties of the fabricated material were improved by reducing the void within the fibers, and that the carbon nanotube/polyimide compound improved the orientation of the carbon nanotubes. The research team was able to fabricate these extremely high-strength and modulus fibers while replacing up to 50% of the carbon nanotubes with low-cost polyimide to lower the overall cost.

Dr. Ku of KIST said, "This research is meaningful because the fabrication cost of carbon-nanotube-based carbon fibers can be greatly reduced by using low-cost polymers." He added, "These novel carbon fibers, which used to be difficult to commercialize due to high cost, are expected to be used in the aerospace, military, and future mobility industries."

More information: Seo Gyun Kim et al, Ultrahigh strength and modulus of polyimide-carbon nanotube based carbon and graphitic fibers with superior electrical and thermal conductivities for advanced composite applications, Composites Part B: Engineering (2022). DOI: 10.1016/j.compositesb.2022.110342

Provided by National Research Council of Science & Technology