This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

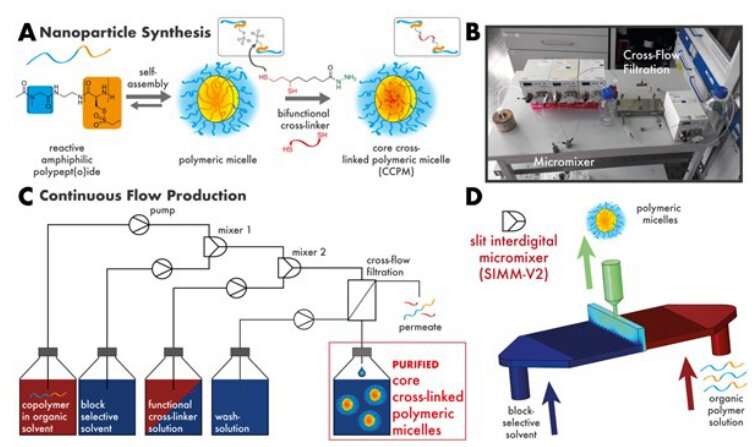

Microfluidic setup for the continuous production of multifunctional nanoparticles

The synthesis of multifunctional nanoparticles is commonly a complex endeavor and hampers the clinical translation of effective nanomedicines. In their most recent work, Matthias Barz and coworkers present a microfluidic setup for the continuous production of drug-loaded core cross-linked polymeric micelles (CCPMs) in a single precisely controlled process. The study is published in the journal Advanced Materials.

The project was performed in collaboration with the Max Planck Institute for Polymer Research, the University of Oslo, and the Fraunhofer Institute for Microengineering and Microsystems (IMM) in Mainz. While Kaloian Koynov and his team helped to characterize the formed CCPMs in biological fluids, the team of the IMM lead by Michael Maskos contributed their immense expertise on microfluidics to develop this unique setup combining two slit interdigital micromixers and a tangential flow filtration unit.

The system enables the controlled formation of micelles in mixer one, the precise core cross-linking in the second mixer, followed by the purification via tangential flow filtration, which removes remaining crosslinkers, unimers, and trances of organic solvents to yield purified functional CCPMs. Combined with functional (prodrug-containing) cross-linkers the process enables the continuous production of drug-loaded CCPMs under specifically controlled conditions, which substantially eases library synthesis, scale-up, certified production, and the clinical translation of lead candidates.

In a first study, the synthesized Paclitaxel-containing CCPMs showed therapeutic efficiency in a B16F10 melanoma model and outperformed the approved Paclitaxel formulation Abraxane, which underlines the therapeutic potential of CCPMs based on polypept(o)ides and microfluidic systems.

More information: Tobias A. Bauer et al, Complex Structures Made Simple—Continuous Flow Production of Core Cross‐Linked Polymeric Micelles for Paclitaxel Pro‐Drug‐Delivery, Advanced Materials (2023). DOI: 10.1002/adma.202210704

Journal information: Advanced Materials

Provided by Leiden University