Aiming to improve joint connection technologies for light-weight and high-strength structures

The research team (led by Professor Yukihiro Matsumoto) formed by Department of Architecture and Civil Engineering of Toyohashi University of Technology and Electronics-Inspired Interdisciplinary Research Institute (EIIRIS) proposed and demonstrated a method for improving the dynamic behavior of bolted connections by using Glass Fiber Reinforced Polymer (GFRP) materials.

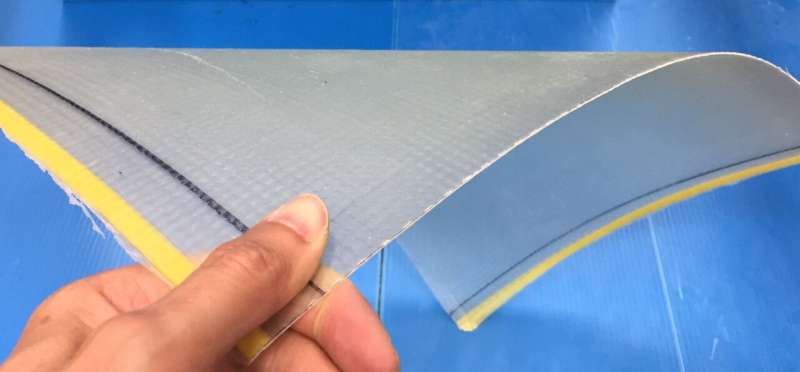

As pultruded GFRP materials used in construction applications have reinforced fiber directions aligned along the axis of the member axis, bolted connections are fragile and at a disadvantage in design. The research team demonstrated that a noticeable increase in bearing strength can be realized by pasting a thin GFRP plate, which uses a multiaxial base material molded by vacuum-assisted resin transfer molding which enables high-quality molding, to the bolted connection. The research team also demonstrated that this method could improve the fragile fracture behavior of the joint connections. The results of this study will enable safer, more secure and lighter building structures with longer lifespans to be designed.

Because of its light weight and high strength, applications for Fiber Reinforced Polymer (FRP) are increasing, such as its use in the repair and reinforcement of existing buildings, pedestrian bridges and floodgates and it is expected that they will be used in emergency repairs of structures and the structure of buildings in the future. The pultrusion method, one of the methods for producing FRP members, can produce long members with ultra-high productivity. It is a commonly used molding method for FRP architectural members. However, because the pultrusion method generally places many reinforced fibers, which ensure the strength and stiffness of FRP materials, in the direction of pultrusion (along the longitudinal axis of the member), it is known to show local damage and brittle fractures around bolt holes when connections are made using bolts, etc. Therefore, care should be taken regarding this fracture behavior.

Therefore, the research team has performed research to minimize the increase in weight and production costs and to improve the dynamic behavior of bolted connections by using vacuum-assisted resin transfer molding, which is used to make parts of ships and blades of wind turbines made of FRP, and by pasting a GFRP plate that is several millimeters thick and has multiple fiber directions.

By reinforcing the necessary areas with only the necessary amount of GFRP, they demonstrated in their experiments that the connection strength of fiber reinforced polymer can be increased significantly without losing the productivity or light-weight properties of FRP. In addition, based on the experimental results and existing design formulas, the research team also proposed a design formula for when their proposed connection reinforcing method is used and successfully provided data that can be applied in design.

The research team leader, Professor Yukihiro Matsumoto, says that "as the name suggests, fiber reinforced polymer is a material that requires the good use of fibers. We have reached this idea by observing the fracture behaviors of connections through previous experiments and collecting information on various FRP molding methods. Though it is simple, what we needed was only the pasting of a thin plate to the connection. I am surprised that good effects were observed by carefully considering fiber direction. I think the useful and general-purpose results were obtained due to the enthusiasm of the Ph.D. students in the determination of experimental variables and the development of an experiment plan."

Going forward, the research team will demonstrate the effectiveness of their proposed connection method through connection experiments assuming construction structures as well as experiments and analyses of full-scale specimens and will promote the development of these reinforced connections, aiming for their application as reinforcement method for existing FRP structures.

The research was published in Polymer Composites and Polymers.

More information: Phan Viet Nhut et al, Pin‐bearing connection strength of single‐bolted pultruded glass fiber‐reinforced polymer profiles strengthened by glass fiber sheet, Polymer Composites (2022). DOI: 10.1002/pc.26774

Quang Tran et al, Multi-Bolted Connection for Pultruded Glass Fiber Reinforced Polymer's Structure: A Study on Strengthening by Multiaxial Glass Fiber Sheets, Polymers (2022). DOI: 10.3390/polym14081561

Provided by Toyohashi University of Technology