December 9, 2019 feature

Shape-programmable dielectric liquid crystal elastomer actuators

Materials scientists aim to use bioinspired soft robots to carry out advanced interactions between humans and robots, but the associated technology remains to be developed. For example, soft actuators must perform quickly with force to deliver programmable shape changes and the devices should be easy to fabricate and energy efficient for untethered applications. In a new report on Science Advances, Zoey S. Davidson and an interdisciplinary research team in the departments of Physical Intelligence, Materials Science and Engineering, and the School of Medicine in Germany, U.S. and Turkey, combined several characteristics of interest using two distinct active materials systems to build soft robots.

The scientists integrated fast and highly efficient actuation with dielectric elastomers (DE) and directed shape programmability using liquid crystal elastomers (LCE). Using topdown photoalignment techniques, they then programmed molecular alignment and localized giant elastic anisotropy into the liquid crystal elastomers. The researchers developed linear actuated liquid crystal elastomer monoliths with strain rates above 120 percent, per second, and an energy conversion efficiency of 20 percent when moving loads above 700 times the weight of the elastomer. The mechanism will allow new research opportunities in miniaturized shape programmability and efficiency alongside increased degrees of freedom for applications in soft robotics in multidisciplinary research.

Material robotics researchers consider compliant actuators to be the missing key to form efficient human and robot interfaces. Compliant soft actuators will ideally be highly efficient, maintain strength-to-weight ratio, work capacity and shape programmability to complete complex functions. Soft actuators with such properties will perform much like an artificial muscle with advanced applications in aerospace, robotics, medical devices, energy harvesting devices and in wearables. Among the varieties of soft actuators explored, dielectric elastomers (DEs) are the most promising. In parallel, liquid crystal elastomers (LCEs) can undergo reversible mechanical deformation using light and thermal actuation near phase transition temperature. Advances in photoalignment and microfabrication have allowed scientists to pre-program liquid crystal alignment in microscopic regions for complex shape morphing. However, existing mechanisms require multistep fabrication methods, while efforts to convey electrical energy to mechanical work using LCE are limited due to the small strain they generate.

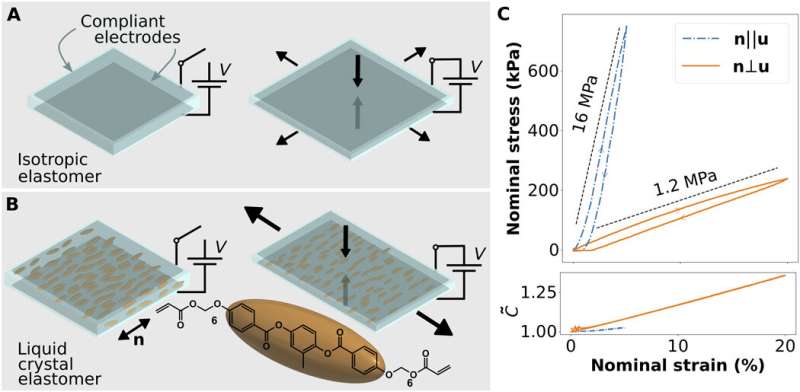

In the present work, Davidson et al. patterned LCE (liquid crystal elastomers) to tailor spatial variation of mechanical compliance (transfer an input force and displacement through elastic body deformation) and develop more effective dielectric elastomer actuators with pre-programmability and direction of actuation (compression). In general, DE (dielectric elastomer) actuators function using electrostatic attraction between two compliant electrodes created on opposite sides of an isotropic DE to engineer a variable resistor-capacitor. High voltage applied to the compliant electrodes can induce an electrostatic pressure known as Maxwell stress to deform the DE; for electrical actuation. This mechanism can produce a higher operating efficiency and higher speed of actuation than those of LCEs. However, despite some impressive results, DE actuators have not yet gained widespread use in soft robotics due to existing challenges that can be overcome using innovative materials to construct next-generation, high-performance DEs with shape programmability.

Davidson et al. directly explored the large mechanical anisotropy (to enhance strain localization) of LCE materials using electric actuation, without relying on molecular rotation. They included recent advances in materials science to construct highly efficient and shape-programmable DEs; referred to as dielectric LCE actuators (DLCEA). The scientists aligned LCE molecules in local domains to achieve electric-driven actuation and allow shape morphing at room temperature to demonstrate large, fast and forceful strains.

The research team developed the LCE films in a two-step process; first, they briefly developed an oligomer, followed by LCE film fabrication using a thiol-acrylate click reaction. They tuned the exact ratio of components, the choice of monomer and dithiol linker, to adjust the desired mechanical properties of the final LCE film. The work produced large areas of well-ordered uniaxial LCE with great elastic anisotropy. The scientists applied compliant grease electrodes to both sides of the LCE film to create the DLCEA (dielectric LCE actuator) devices.

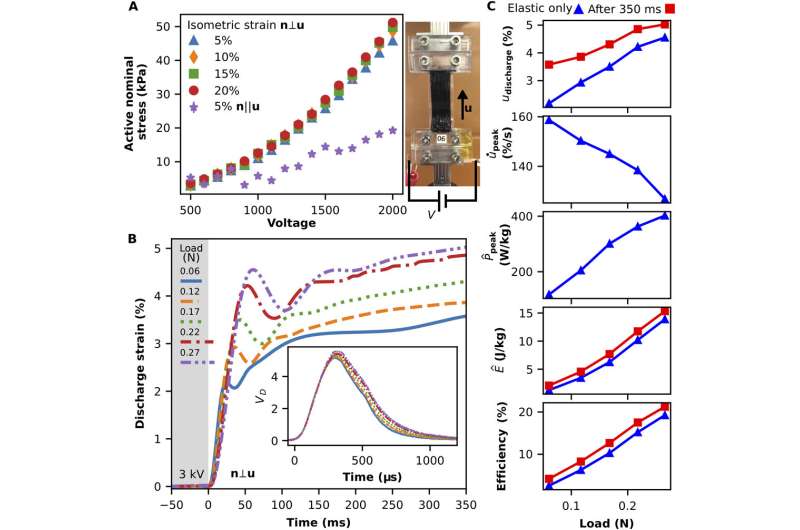

Davidson et al. then characterized (tested) the materials starting with monodomain uniaxially aligned LCE films. Next, they tested the uniaxial DLCEAs in isometric (constant strain) and isotonic (constant force) configurations. For example, during isometric tests, they applied initial strains to DLCEA devices and allowed relaxation before applying a high voltage for electric actuation. During isopotential tests (where every point in a region or space is at the same potential), the scientists strained the DLCEA under a constant voltage to indicate expected actuation.

Using the same DLCEA, the research team performed isotonic tests by suspending a variety of weights from the free-end of the device to generate constant load forces and initial nominal strains. They then abruptly discharged the weighted DLCEA device and captured subsequent motion using a high-speed video. As the experimental load and strain increased, the capacitance of DLCEA increased.

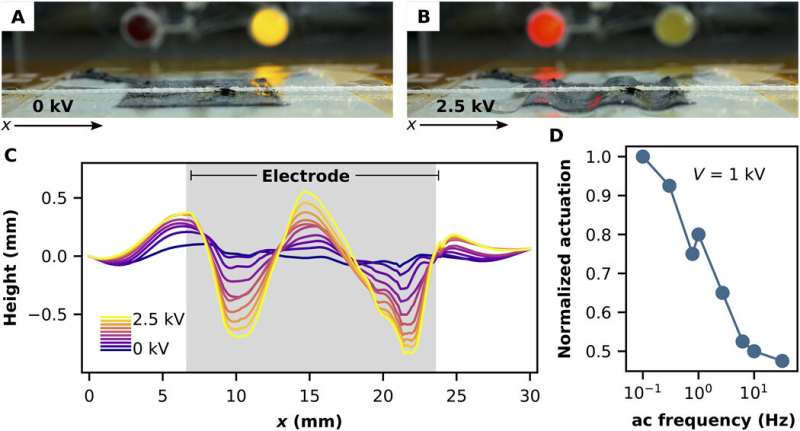

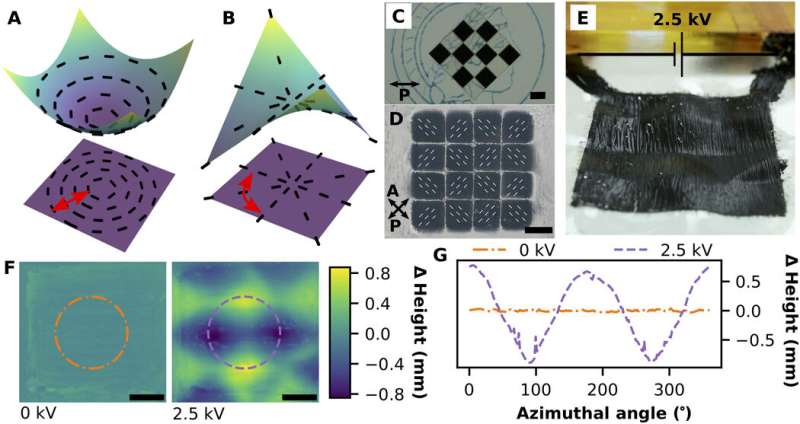

During complex shape actuation, boundary conditions played a significant role to determine the shape change of DLCEA. The research team understood the role of boundary conditions by characterizing the buckling effect caused by the elastomer's expansion between fixed boundaries, they observed increasing buckling amplitude with increasing voltage. The actuation peak was also another characteristic of interest for DLCEA applications, the scientists measured the change in actuation amplitude as a function of applied frequency using a sinusoidally varying 1-kV potential. Although the actuation amplitude decayed exponentially with frequency, the researchers measured the parameters (50 µm) at 30 Hz and 1 kV.

To then demonstrate the ability to pre-program complex patterns in 2-D, followed by electrical actuation of the films into 3-D forms, the scientists designed spatially varying LCE director configurations. They observed the LCE film to buckle out of plane with locally positive or negative Gaussian curvature to form cones or anti-cone deformation in elastic media. Davidson et al. observed the locally programmed height change and accompanying formation of Gaussian curvature in the experimental device. The researchers credit the observed high efficiency in the system to the anisotropy of elastic modulus and Poisson's ratio. The material Poisson's ratio anisotropy is an important feature that can allow programmed shape change actuation. By mechanism, the actuated or compressed LCE can transversely expand to create a shape change. The experimental method developed in this work can be generalized to create a large variety of programmable shape changes. Consequently, when an electric field is applied to the DLCEA, the device can produce twisted motions, where the magnitude will depend on the material's intrinsic properties and on the LCE geometry.

In this way, Zoey S. Davidson and colleagues combined desired characteristics of DEs and LCEs within a single material platform to form electrically actuated DLCEAs with superior actuation performance. The devices displayed high energy conversion efficiency (20 percent) high actuation speed (120 percent per second) and programmable shape change from 2-D to 3-D with more than 1,800 percent out-of-plane stroke. For larger actuation forces, the research team consider multilayer DLCEA stacks.

The insights provided in this work into active materials integration techniques and mechanisms of electro-actuation can offer more exciting opportunities. The methods can be coupled with 3-D printing, origami and kirigami actuation strategies to create multifunctional soft robots with low cost and sustainable materials as frugal inventions. The developed mechanism can also be applied to other technologies such as energy harvesting and storage, for medical devices, wearable technology and aerospace.

More information: Zoey S. Davidson et al. Monolithic shape-programmable dielectric liquid crystal elastomer actuators, Science Advances (2019). DOI: 10.1126/sciadv.aay0855

Ehsan Hajiesmaili et al. Reconfigurable shape-morphing dielectric elastomers using spatially varying electric fields, Nature Communications (2019). DOI: 10.1038/s41467-018-08094-w

C. D. Modes et al. Gaussian curvature from flat elastica sheets, Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences (2010). DOI: 10.1098/rspa.2010.0352

Journal information: Science Advances , Nature Communications

© 2019 Science X Network