Capturing real-time data as nanofibers form makes electrospinning more affordable and effective

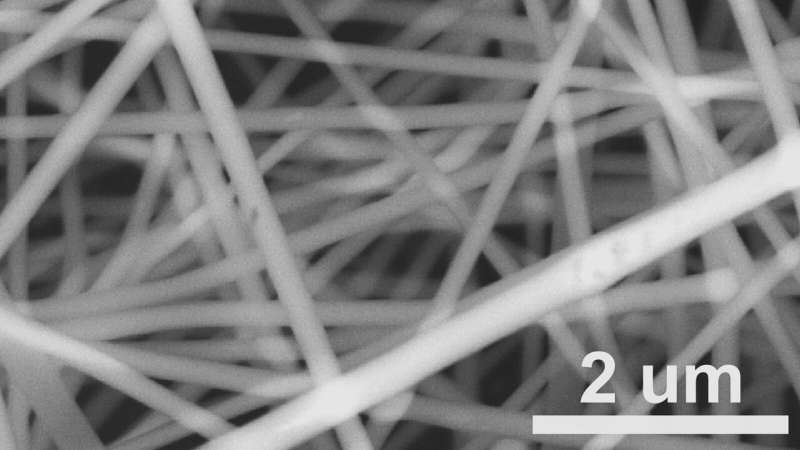

Electrospinning, a nanofiber fabrication method, can produce nanometer- to micrometer-diameter ceramic, polymer, and metallic fibers of various compositions for a wide spectrum of applications: tissue engineering, filtration, fuel cells and lithium batteries. These materials have unique properties because of their high-aspect-ratio morphology and large surface area.

Yet their development has largely been by trial and error, making it difficult to reproduce reliably in industrial settings. This challenge stems from a lack of understanding of the underlying dynamics during the process, which involves more than 10 control parameters.

The U.S. Department of Energy's (DOE) Argonne National Laboratory is taking the guesswork out of electrospinning by leveraging its unique suite of capabilities to build a database that correlates electrospinning machine parameters with nanofiber properties. The suite will allow companies to design materials optimized for specific applications at top speed, while also making possible real-time feedback and control on the manufacturing floor.

The advanced electrospinning facility is part of Argonne's advanced manufacturing science and engineering effort to accelerate materials development and manufacturing processes by developing platform technologies augmented with state-of-the-art computing and diagnostics systems. This combination enables predictive science that reduces costly trial-and-error prototyping. The project is funded by Argonne's manufacturing Laboratory-Directed Research and Development (LDRD) program.

Argonne is in a unique position to advance electrospinning technology because of a combination of expertise in materials development and scaleup, along with the unique diagnostic capabilities available at the Advanced Photon Source (APS), a DOE Office of Science User Facility and the nation's highest-energy synchrotron X-ray source.

The researchers, led by Argonne materials scientist Yuepeng Zhang, are conducting in-situ X-ray measurements at the 12 ID-B beamline at the APS. The measurements capture real-time structural, physical and chemical information from nanofibers as they form and change during processing, facilitating correlation with processing parameters (e.g., voltage, working distance and precursor viscosity).

Zhang says, "The measurements provide—for the first time—a systematic understanding of the spinning and annealing processes to control and enhance product performance."

The next step is to enter the X-ray data into machine-learning algorithms that run on high-performance computing facilities at Argonne. These computations will further optimize speed, reduce material defects, predict novel properties and eliminate costly trial-and-error prototyping.

The electrospinning capability also can be adapted for use with roll-to-roll manufacturing processes (which involve continuous processing of a flexible substrate as it's transferred between two moving rolls of material) to accelerate commercialization and reduce costs. Argonne is demonstrating the roll-to-roll concept and its first application by producing large-area LLZO solid-state electrolytes for energy storage applications.

Industry can collaborate with experts at Argonne to develop electrospinning processes for their existing materials, as well as collaborate on new or emerging (composite) materials and designs, including scaleup.

Provided by Argonne National Laboratory