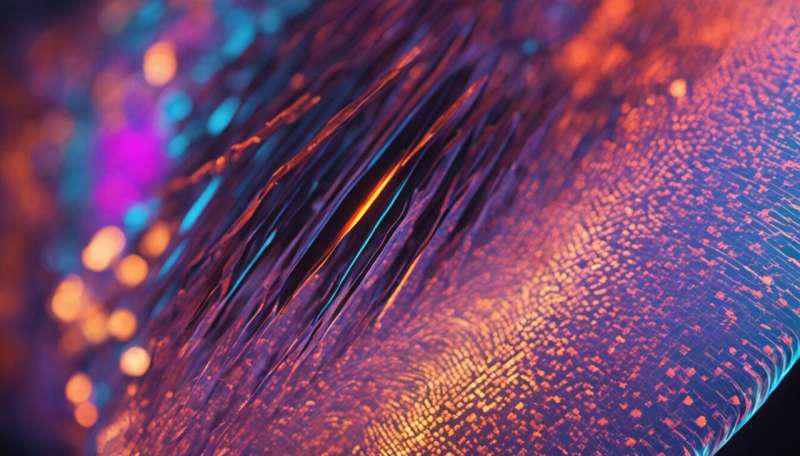

The potential of flexible OLEDs as an innovative surface material

High-visibility clothing is an important element of any motorcyclist's safety routine. Such products usually incorporate reflective strips for added visibility at night-time, but thanks to organic electronics, rider safety will now be improved further. Partners of the EU-funded PI-SCALE project are focusing on various applications of OLEDs, including their integration into textile designs.

According to a press release by the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, OLEDs are being incorporated into a motorcycle jacket. "Used as a material for clothing, OLEDs not only can trigger completely new aesthetic trends, they can also provide active illumination instead of just limited reflectance. This enhanced visibility from all angles means the wearer can be seen more clearly, increasing rider safety."

The same press release notes that the technology involves "fabricating the OLEDs on flexible substrates such as plastic films and connecting them to conductive threading for their supply of electrical power." Quoted in the press release, Claudia Keibler-Willner, head of department at the Fraunhofer FEP, summarises the outcome: "We have taken a major step forward in economical fabrication processes for OLEDs. The results are impressive: the OLED shines very uniformly." She adds: "The use of the roll-to-roll process also promises considerable cost reductions for future components. By combining printed and vaporized layers, process throughput and production speed can be increased up to 100 times."

Flexible OLEDs are light sources that are "ultra-thin (<0.2 mm), highly bendable, very lightweight, and even transparent," as explained in a flyer on the project website. "They can be made or cut to any shape or size, and can be integrated into formed components or seamlessly bonded onto curved surfaces."

From lab to mass production

The ongoing PI-SCALE (Bringing flexible organic electronics to pilot innovation scale) project was launched to speed up the process of market acceptance of flexible OLEDs. As noted in a factsheet on the project website, "PI-SCALE has the ambition to create a World-leading open access pilot line for companies interested in the manufacture and system-level integration of flexible OLEDs into products." The factsheet states: "The pilot line is positioned to bridge the gap between R&D and mass production, offering small-to-medium scale pre-production runs of customised flexible OLED devices with a volume of up to 5000 m2 of OLEDs/year."

The factsheet adds that preliminary products will serve various industries, including architectural lighting, automotive, aerospace and consumer electronics. Flexible OLEDs will be tested in four launching customer application cases. "All business cases are targeting existing markets, where the companies involved have well developed dissemination channels which will contribute to the anticipated flexible OLED market introduction." The partners believe the project will contribute to secure, clean and efficient energy.

More information: PI-SCALE project website: pi-scale.eu/

Provided by CORDIS