Thermally-painted metasurfaces yield perfect light absorbers for high-tech applications

Researchers have discovered that the ancient technique of heating metal to create vibrant colors creates a nanostructured surface that acts as a perfect light absorber. Perfect light absorbers—materials that absorb more than 99% of a certain color—can be used for sensing, solar panels, anti-counterfeiting and stealth technologies.

In the journal Optical Materials Express, researchers from Case Western Reserve University in Ohio report their insights into how colors are generated on heated metal surfaces and apply those findings to create a nickel thin-film that perfectly absorbs red light.

"We found that a 3,000-year-old metallurgy technique is actually one of the simplest examples of a metasurface—artificial surfaces with subwavelength features that impart unique electromagnetic properties," said Giuseppe Strangi, a member of the Case Western Reserve University research team. "Creating color changes by depositing a single metal layer opens up new aesthetic possibilities in metalworking, as well as applications such as shielding devices from electromagnetic signals that cause noise and interference."

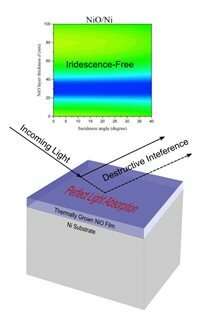

Unlike the iridescent colors of water bubbles and butterfly wings, which change depending on the viewing angle, the thin oxide films produced by heating metal maintain their colors at all angles. This could make the heat-induced color useful for making holograms to protect currency and metal products from counterfeiting.

A simple approach

Scientists have previously demonstrated perfect light absorption using ultrathin absorptive materials on metals or with highly-engineered nanostructures. However, these materials require at least two material depositions using nanolithography fabrication methods that are expensive, time consuming and hard to reproduce.

"We showed that perfect light absorption could be realized using a simple thin-film with the right combination of oxide and metallic substrate," said Strangi. "This combination naturally occurs with certain metals like the nickel and titanium we used in this study."

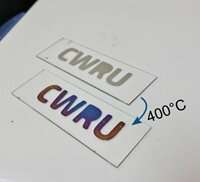

To demonstrate their technique, the researchers deposited 150 nanometers of nickel or titanium on silicon and then heated the films for 20 to 40 minutes at 400 ?C to form an oxide layer. Analysis of the samples' absorption properties showed that the nickel films baked for 40 minutes absorbed approximately 99.94% of red light. The researchers also demonstrated that the light absorption could be tuned across visible and near-infrared wavelengths by modifying the heating duration, which changes the thickness of the oxide layer.

How it works

Perfect light absorption occurs in the heated metal because light rays emerging from the oxide layer and the metal substrate come together in such a way that they cancel each other out—a phenomenon known as total destructive interference. Any remaining light is absorbed inside the metal substrate.

"This method of creating perfect absorption is very practical due to its simplicity and reproducibility," said Strangi. "The oxide layer makes the surface scratch resistant and protects it from further oxidation."

The researchers plan to perform additional experiments to determine if high-resolution patterns can be formed by growing metal oxide layers. They are also working to develop gas sensors using the perfect light absorbers.

More information: Theodore Letsou et al, Heat-induced perfect light absorption in thin-film metasurfaces for structural coloring [Invited], Optical Materials Express (2019). DOI: 10.1364/OME.9.001386

Journal information: Optical Materials Express

Provided by Optical Society of America