Rare earth magnet recycling is a grind, but new process takes a simpler approach

A new recycling process developed at the U.S. Department of Energy's Critical Materials Institute (CMI) turns discarded hard disk drive (HDD) magnets into new magnet material in a few steps, and tackles both the economic and environmental issues typically associated with mining e-waste for valuable materials.

Ryan Ott, a scientist at Ames Laboratory and a member of the CMI research team, said that with an ever-increasing amount of discarded electronics globally, it made sense to focus on the most ubiquitous source of valuable rare earth magnets in that waste stream—hard disk drives, which have a relatively centralized scrap source.

"There are a lot of ways to go about getting the rare-earth elements out of e-waste, and some of them are very effective, but some create unwanted by-products and the recovered elements still need to be incorporated into a new application," said Ott. "Here we have eliminated as many processing steps as we can, and go straight from the discarded magnet to an end product, which is a new magnet."

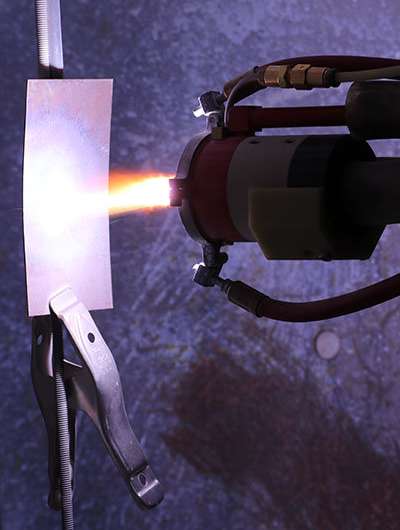

Scrapped HDD magnets are collected, then any protective coatings are removed. The magnets are crushed into powder, which is then deposited on a substrate using plasma spray to synthesize coatings ½ to 1 mm thick. The properties of the end product are customizable depending on processing controls.

While the new magnetic material cannot retain the exceptional magnetic properties of the original material, it potentially fills market needs for an economical choice where the performance of a high-strength rare-earth magnet is not required, but lower performance magnets like ferrites are not sufficient.

The method is also an efficient way to produce strong magnets for small places, like sleek hand-held electronics.

"This waste reduction aspect of this process is really two-fold; we're not only reusing end-of-life magnets," said Ott. "We are also reducing the amount of manufacturing waste produced in making thin and small geometry magnets out of larger bulk materials."

Provided by Ames Laboratory