Researchers 'get rough' with nanomaterials to eliminate problematic stickiness caused by smooth surfaces

The smaller the object, especially at the atomic or subatomic level, the stranger it behaves. For example, as technological devices become smaller and smaller, the even smaller parts are more prone to adhesion or "stickiness." When small-size parts come into contact, they spontaneously stick together and cannot easily be pulled apart. However, recent research at the University of Pittsburgh may "unstick" the problem and improve the next generation of microdevices increasingly used in everyday life.

"Surfaces tend to attract each other via electronic or chemical interactions," says Tevis Jacobs, assistant professor of mechanical engineering and materials science at Pitt's Swanson School of Engineering. "This is particularly problematic as things become small. You can see this when you grind coffee. The whole beans don't stick to the side of the grinder, but a fine grind will stick to everything, especially on a dry day."

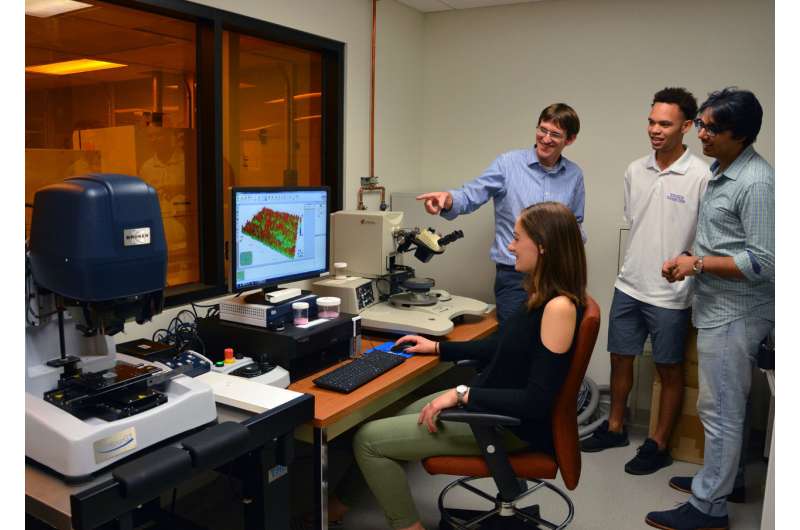

Dr. Jacobs is the principal investigator for the study "Understanding and Leveraging the Effect of Nanoscale Roughness on Macroscale Adhesion," which received $305,123 from the National Science Foundation (NSF) to measure surface roughness and characterize the fundamental relationship between adhesion and roughness at small sizes. Dr. Jacobs and his team will determine when tiny objects prefer to stick together.

"One reason that small parts stick more readily than large parts is the surface-to-volume ratio," says Dr. Jacobs. "For large parts, there is a lot of volume relative to surface, so the adhesion is relatively weak compared to body forces, like gravity. When the parts become small, the surface forces become larger relative to the body forces and the parts will spontaneously stick."

For many engineering materials, increasing an object's surface roughness will make it less likely for the small parts to stick together. The general reason why roughness reduces adhesion is well known.

"Picture a cube with one-inch sides sitting on a table. If the surfaces are perfectly flat, then it will make contact with the table over an area of one square inch," Dr. Jacobs explains. "If you grind the surface with sandpaper and put it back on the table, the roughness will prevent close contact in some areas. In fact, the cube might be supported by only a small number of contact points. The "true contact area" may be 1000 times smaller than one square inch."

The Pitt research team is developing and testing analytical and numerical models to be able to make quantitativeJacobs Alt Adhesion Int predictions of adhesion between rough surfaces. This work will also guide engineers in intentionally modifying roughness to achieve a desired level of adhesion.

A better understanding of how to reduce stickiness in small sizes will likely have the biggest impact on microdevices, which are commonly used in consumer electronics, biomedical devices, the semiconductor industry, and defense applications. The research is also applicable to the new manufacturing techniques being pioneered to create these microdevices, allowing manufacturers to avoid adhesion-related problems.

"A classic example of adhesion causing a problem is the Digital Micromirror Device from Texas Instruments," Dr. Jacobs says. "This projector, like the one used in auditoriums, involves a series of microelectronic devices that move tiny mirrors to make the projector function. The product was almost completely undone by adhesion in the microelectronic devices. They would get stuck in a specific position and be unable to move, resulting in a 'stuck pixel' on the display."

The Pitt researchers are not only understanding surface roughness and its effect on surface adhesion, they are also developing methods to modify the microdevices to achieve a desired level of adhesion.

"There are many different models describing roughness and adhesion, but none are well verified experimentally," says Dr. Jacobs. "We are using brand new techniques to measure the roughness, to experiment with different types of roughness, and to measure the resulting adhesion. Our goal is to test the existing models of adhesion and roughness and to establish new models that are more quantitative and predictive."

In 2015, Dr. Jacobs received an NSF grant to observe and measure the atomic surface structure of nanomaterials using electron microscopy. This new study is building on his past research and will employ a combination of transmission electron microscopy to characterize previously unmeasured surface scales and a custom micromechanical tester to measure surface adhesion.

Provided by University of Pittsburgh