Researchers convert 80 percent of biomass into high-value products via new strategy

The three main components of non-edible plant matter can now be turned into high-value products in economically favorable yields. Using the concept of an integrated biorefinery, researchers showed how multiple products are created. The streams are similar to those used in a petroleum refinery. With the new approach, non-edible plant matter could become a promising alternative source of carbon. The resulting products—dissolving pulp, furfural, carbon foam and battery anodes—have established markets, reducing the risk for the first commercial plant.

This technology could enable a biorefinery that is cost-competitive with petroleum. Further, it could expand to produce fermentable sugars, advanced biofuels or specialty chemicals. The technology is attractive for investment. A techno-economic analysis estimates an overall revenue of $500 per dry megaton. This results in an internal rate of return of over 30 percent.

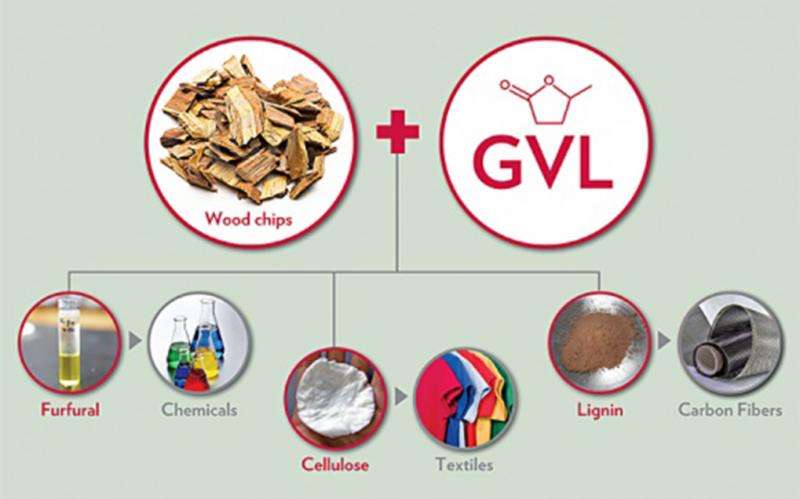

The production of renewable chemicals and biofuels must be cost-competitive with petroleum-derived equivalents to be accepted by markets. At the Great Lakes Bioenergy Research Center, one of three U.S. Department of Energy (DOE) Bioenergy Research Centers, scientists propose a biomass conversion strategy utilizing gamma valerolactone (GVL)—a solvent derived from plant material that maximizes the conversion of lignocellulosic biomass. Using this method, up to 80 percent of the biomass can be converted into high-value products that can be commercialized, providing the opportunity for successful translation to a viable commercial process.

Their fractionation method preserves the value of all three primary biomass components: cellulose, which is converted into dissolving pulp for fibers and chemical production; hemicellulose, which is converted into furfural, a building block chemical; and lignin, which is converted into carbon products (carbon foam, fibers or battery anodes). Because these products are all existing targets for pulp mills, they can be directly introduced into current markets, minimizing market risk for the first commercial plant. The overall revenue of the process is about $500 per dry megaton of biomass, which combined with low total cost results in an internal rate of return over 30 percent. Once de-risked, the technology can be extended to produce fermentable sugars, advanced biofuels or other specialty chemicals. This research aligns closely with DOE's environmental and energy independence missions.

More information: David Martin Alonso et al. Increasing the revenue from lignocellulosic biomass: Maximizing feedstock utilization, Science Advances (2017). DOI: 10.1126/sciadv.1603301

Journal information: Science Advances

Provided by US Department of Energy