Making houses in Sweden with additive manufacturing

In a collaborative project worth SEK 35 million, researchers and external partners are together developing technology to make full-scale 3D prints of cellulos- based material. It is not a matter of small prints – the objective is to make houses.

The impact of digitalisation on the manufacturing and construction industry is still in its infancy. However, a large project with based in Sliperiet at Umeå Arts Campus, a part of Umeå University, is now setting the pace in the region's journey to the forefront of this field.

"The idea of the project is to develop a technology that can be used in reinforcing the manufacturing industry in the region. For Sliperiet the project, entitled the +Project, is a part of the strategy of forming collaboration in an open and interdisciplinary innovative environment. Here, meetings and collaborations are created between various scientific areas and together with companies in the region," says Marlene Johansson, director of Sliperiet.

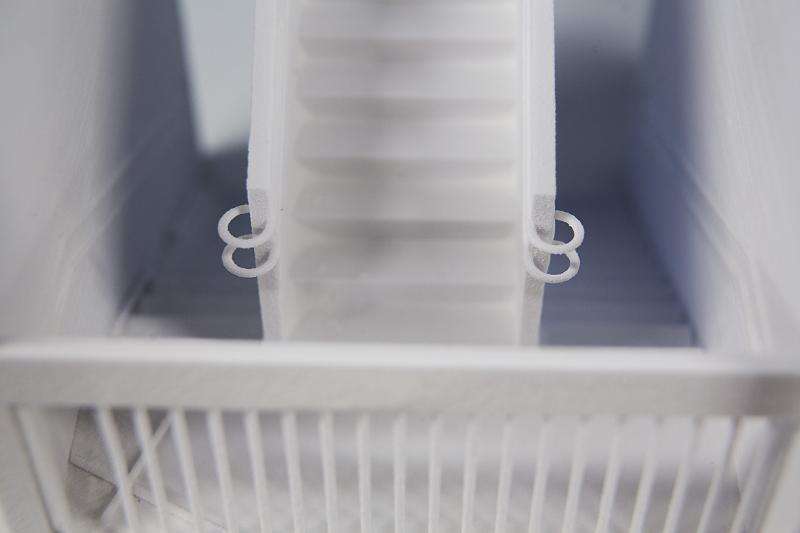

One of the sub-goals of the project is to produce cellulose-based materials for full-scale 3D printing of everything from weather-stripping and doors, to walls and, in the end, complete houses. Sliperiet has, together with various collaborating partners, received SEK 17.6 million from EU Structural Funds in an interdisciplinary development project aimed at building a strong area of innovation and a regional cluster in digital manufacturing, sustainable building and 3D technology. In total, the collaborative project is worth SEK 35.3 million.

The target audiences for the +Project are small and medium-sized industries in the construction and wood sector, as well as creative markets such as architecture, design and IT. Entrepreneurs, creators and companies will, in collaboration with the university and research institutes, develop prototypes for products and services based on the regional infrastructure and raw materials – prototypes that can be commercialised by regional companies and entrepreneurs. The plan is also to explore new circular models for business and production and to create a competence centre for sustainable building and administering. At the end of the project in 2018, a World Expo will be created in order to position the region in the lead of digital manufacturing and sustainable building.

At Umeå University, the following collaborating partners are involved: Umeå School of Architecture, Umeå School of Business and Economics, the Department of Informatics and the Department of Applied Physics and Electronics. The project is also made up of the research institutes: the Interactive Institute (Swedish ICT) and SP Processum, as well as of companies such as Revenues, White Architects, and the Network for sustainable building and administering in cold climates. Umeå municipality and Region Västerbotten offer their support by co-funding the project.

There are rapid developments within the area of digital manufacturing in construction, with technology such as large scale cement 3D printers being developed. With our project, we hope to help put the region at the forefront of this innovation area. Digitalisation, and through it mass-customization, can provide incredibly exciting opportunities for the regional forest and construction industry, and create sustainable business opportunities based on our natural resources," says Linnéa Therese Dimitriou, Creative Director at Sliperiet.

Provided by Umea University