How power network components behave when subjected to extreme water pressures

At a unique lab in Trondheim, Norway, Siemens researchers are examining how power network components behave when subjected to extreme water pressures. In 2020, such a system will begin supplying energy to large oil and natural gas production sites at a depth of 3,000 meters.

Jan Erik Lystad says that pressure doesn't bother him much. A glance at the 60-year-old Norwegian engineer, who joined Siemens 14 years ago, makes you believe him. With his jeans, blue checked flannel shirt, and hands-in-pockets stance, Lystad looks as though nothing could faze him. He has spent all his life in Trondheim, where he went to college and raised his children. He perfectly reflects the qualities of this picturesque city of 180,000 inhabitants, where meter maids ride bicycles and continuity is important. However, Trondheim's sedate facade hides a veritable volcano of bright ideas and innovations, powered by scientists such as Lystad, dozens of research institutes, and thousands of students at the city's technical university. The epicenter of this volcano is often the Siemens research center in Bratsbergveien, just a few kilometers from downtown Trondheim. In 2012, researchers here developed the world's first electric ferry. And now another eruption is imminent, as Lystad's lab is literally operating under high pressure.

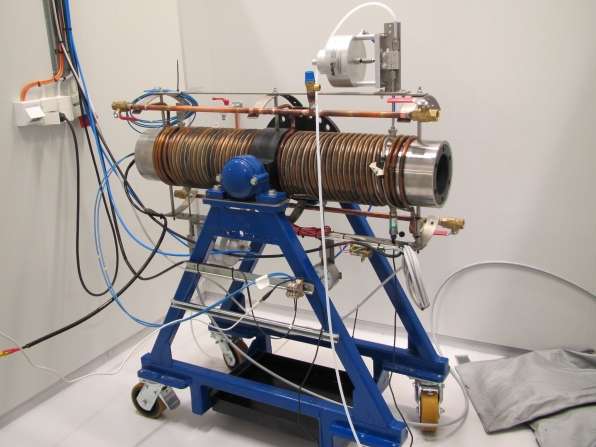

"We have a kind of torture chamber for technical components," he says. "We put parts under enormous pressure. The technology has to withstand up to 460 bar—that's how high the pressure is at a depth of 4,600 meters." However, Lystad's unique torture chamber is not so much a place of agony as of pioneering work. In the lab, ten engineers test the components for a power network that will supply energy to future deep sea factories. Beginning in 2020, the Norwegian energy company Statoil plans to use such self-sufficient oil and gas extraction factories on the ocean floor.

Siemens technology will supply the pumps and compressors with electricity. By then, individual network components will have to demonstrate that they can withstand the extreme conditions found at depths of at least 3,000 meters under the sea. This is a huge challenge, as researchers have had no experience with network components at such depths, where they will have to withstand 300 kilograms of pressure per square centimeter in perpetual darkness. "Transformers, frequency converters, and switchgears have to operate flawlessly in such environments. What's more, they have to do so for 30 years, because it would be difficult to service them down there," says Lystad. "Only if electricity flows with absolute reliability will it be possible to relocate today's production platforms to the ocean floor."

Such self-sufficient deep-sea factories with their own power supply systems are not yet available. Although there are already a few facilities that operate on the ocean floor, they are connected to floating platforms and have to be individually supplied with electricity through dozens of cables. And the raw materials that the facilities pump out of the ground are still processed on the surface as well. Subsea technologies currently work only in shallow waters. Moreover, they are expensive and complex. As a result, the majority of the oil and natural gas produced offshore today is still pumped by traditional production platforms. Only a small percentage is extracted directly on the ocean floor.

Operating on the ocean floor

Lystad believes that in the future this ratio will be reversed. "The trend is toward previously unexploited deposits in the deep sea and the Arctic, which are difficult to reach with conventional technology," he says. Self-sufficient underwater factories would thus make sense in such areas. "Although conditions on the ocean floor are extreme compared to those on the surface, they are also stable. Temperatures stay at around 4° C and there are no storms or icebergs," Lystad explains. "This makes deep-sea facilities much less prone to faults and more cost-efficient than conventional systems." Their only connections to the surface would be a power cable and a pipeline, which could reach land whenever the facilities are not too far offshore. A deep-sea-compatible power supply could also boost a facility's production capacity—for example, by ensuring that many more pumps could be in constant operation. "The new technology would enable us to exploit around 60 percent of a reservoir. We can't achieve more than 40 percent with current subsea technology," says Lystad.

A soft hum can be heard in the "torture chamber." Cables and connectors are clearly arranged on the floor. The researchers have been able to use the brand-new Pressure Test Lab for about two years; previously the building housed an electric heating system factory. After donning protective goggles, Lystad walks slowly through the hall. Next to him is a series of 19 reinforced concrete chambers. Each of these small cells has a blue metal door. On each door hangs a laptop showing diagrams and rows of numbers on its display. One of the doors is open, revealing a silver cylinder in the middle of the cell. Several cables jut out of the ends of a tube that is about two meters long. "These are our pressure vessels," says Lystad as he knocks on one of the cylinders. "Each cylinder consists of 150 kilograms of solid metal. If we want to test a component, we put it in the cylinder. We then fill the cylinder with oil and seal it shut. The pressure is raised to as high as 460 bar."

According to Lystad, the oil's purpose is to distribute the enormous pressure. "Before the grid component is actually lowered underwater, its entire housing is filled with oil," he says. "This allows us to make the system more compact than conventional air-filled containers. What's more, we won't need any complex cooling systems, since the oil dissipates heat." Lystad walks three steps to the other end of the chamber. "The cell surrounding the cylinder is open at the top and serves as a safety barrier. If anything goes wrong during the pressure tests, the energy will escape through the open top and the pieces will fly against the inside wall," he says.

Transistors, connectors, and other components are "tortured" for up to six months during continuous operation inside the tube. The engineers not only check to see if the components can withstand the high pressures and remain functional; they also want to determine if the parts wear out after 20 years of operation. To conduct such an endurance test, the engineers equip the cylinder with a heating loop that keeps the temperature at a constant 95° C to simulate the aging process. Once the Siemens experts are done "torturing" the components, they take the parts out of the pressure vessel and clean off the oil, which is then filtered and reused. "This is followed by a mechanical inspection," says Lystad. "Basically, we take the components apart and look for tiny cracks or deformations." The technology isn't considered deep-sea compatible until the inspectors cannot discover any faults with their trained eyes. However, Lystad points out that parts are not always up to scratch. "It's a major challenge to find components that can withstand such extreme conditions, because no manufacturer offers products that are especially designed for such depths. We are continuously entering uncharted territory."

Eternal darkness

Once all the parts have passed the tests, they are combined into a network component and firmly screwed onto a platform that is covered with zinc plates to protect it from salt water corrosion. Finally the engineers cover the system with a housing. They have already completed their first deep-sea transformer and dipped the huge container into the sea, even though this "bath" was only a test conducted in Trondheim's harbor. Also a 35-ton switching station is already assembled. The giant stands next to the pressure lab in the hall, looking like a submarine in dry dock. A frequency converter, which ensures that oil pumps or gas compressors are supplied with the right operating voltage, is to be completed by the end of 2015. At that point the assembly will weigh around 120 tons. "We will then combine all three components into a single network for the final test," says Lystad. During the test they will be submerged into the sea's eternal darkness for the first time.

Lystad scratches his beard in satisfaction. "It's fascinating to work in regions most people regard as totally inaccessible," he says. He is delighted by his young colleagues' progress. "We're a big happy family and we work closely with the Norwegian University of Science and Technology in Trondheim. I studied there and so did all my engineers." Continuity and progress also play a big role in Lystad's life beyond the Siemens research center in Bratsbergveien. He has a little farm on a small island near Trondheim. He often goes fishing there with his grandchildren—and thinks about his other passion: the dark depths of the sea.

Provided by Siemens