Measuring speed in flying inkjet drops

Physicists from the FOM workgroup Physics of Fluids (MESA+) at the University of Twente and from Océ-Technologies have developed a method to measure detailed speed data in flying inkjet drops. Their research was recently published in the first issue of the new Journal Physical Review Applied.

Inkjet technology is the most used technology for printing documents. Drop-on-demand inkjet printing is a much-used method in which an ink drop is produced at the moment it is needed. These ink drops typically have a diameter of about thirty micrometres, about three times as thin as a human hair. Due to the high reproducibility of the drops and the high resolution that can be achieved, the technique is also particularly suitable for other purposes, such as electric circuits, organic LEDs and the popular technology of 3D printing.

Photographing drops

For the design of new printer heads, researchers often use numerical models that can predict the functioning of the printer heads. However, it is difficult to confirm these models experimentally, as the drops are so small and fast that it is hard to obtain a good image of them.

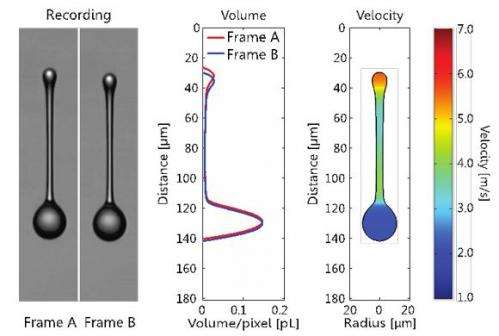

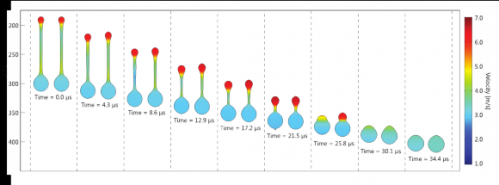

To photograph the drops, which move with a speed of ten metres per second, microscopically and without motion blur, the FOM physicists use an exposure time of nanoseconds. They achieve this exposure time by making use of a unique optical detection technique: illumination by light-induced fluorescence. With this technique the researchers illuminate a fluorescent medium with a laser pulse as a result of which an intense light flash of just eight nanoseconds is generated. By exposing and photographing the drop on two occasions shortly after each other the researchers can make a good image of how the ink moves and from this derive the fluid speed within the drop. In the article in Physical Review Applied, the scientists applied the method to a drop from a printer head from Océ-Technologies and the time between two photos of the same drop was just 600 nanoseconds.

Testing models

The researchers use the drop volumes and speeds measured to test the prediction of numerical models. In the article they make a comparison with a theoretical slender jet approximation model. The measured contour of the drop and the speed profile were used as a starting point for the model. Next physicists compared the numerically calculated drop formation with the experimental data. The comparison revealed a perfect agreement between theory and experiment. Océ-Technologies now uses this method for the design of new print applications.

More information: "Velocity Profile inside Piezoacoustic Inkjet Droplets in Flight: Comparison between Experiment and Numerical Simulation." Arjan van der Bos, Mark-Jan van der Meulen, Theo Driessen, Marc van den Berg, Hans Reinten, Herman Wijshoff, Michel Versluis, and Detlef Lohse. Phys. Rev. Applied 1, 014004 – Published 27 February 2014, journals.aps.org/prapplied/abs … sRevApplied.1.014004

Provided by University of Twente